1. General Information About Pipe Plugs

1.1 What is The Pipe Plug?

Pipe plugs are designed for temporary sealing of pipelines in sewerage, water line systems for maintenance or non-pressurized line testing as well as gas, oil and hydrocarbon pipelines.

Pipe plugs consist of two main products;

- Inflatable Pipe Plugs

- Inflatable Pipe Plugs with Bypass (Flow-through Pipe Plug)

They can be used for three cases:

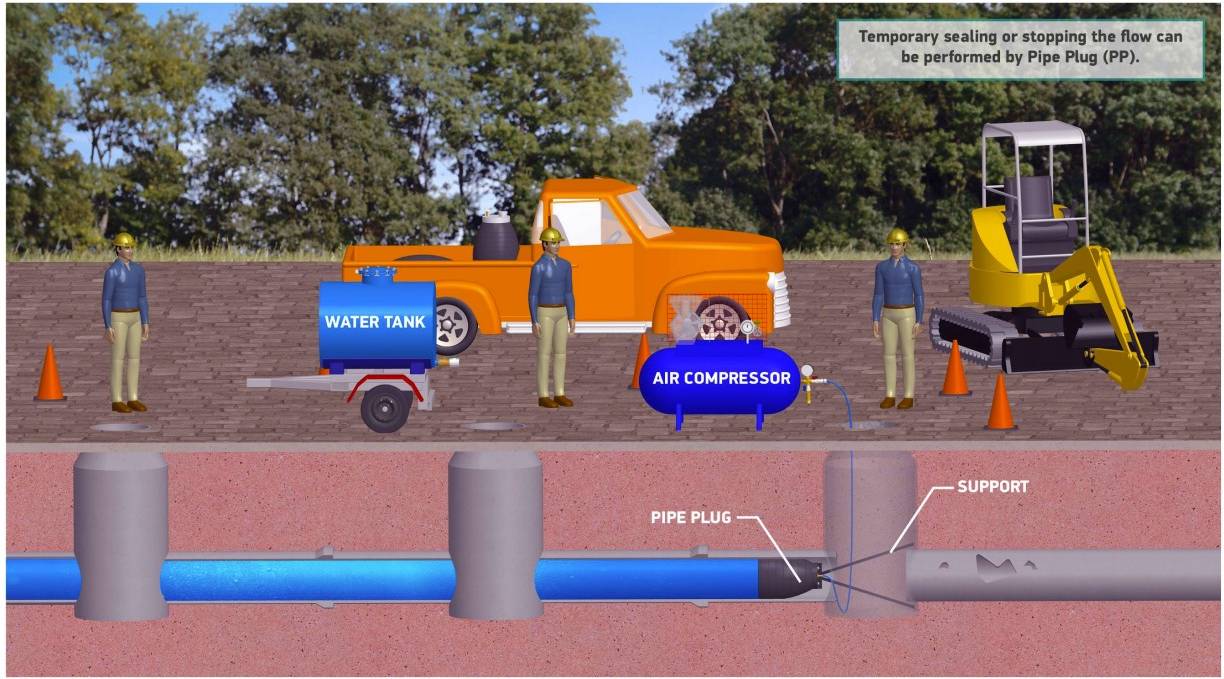

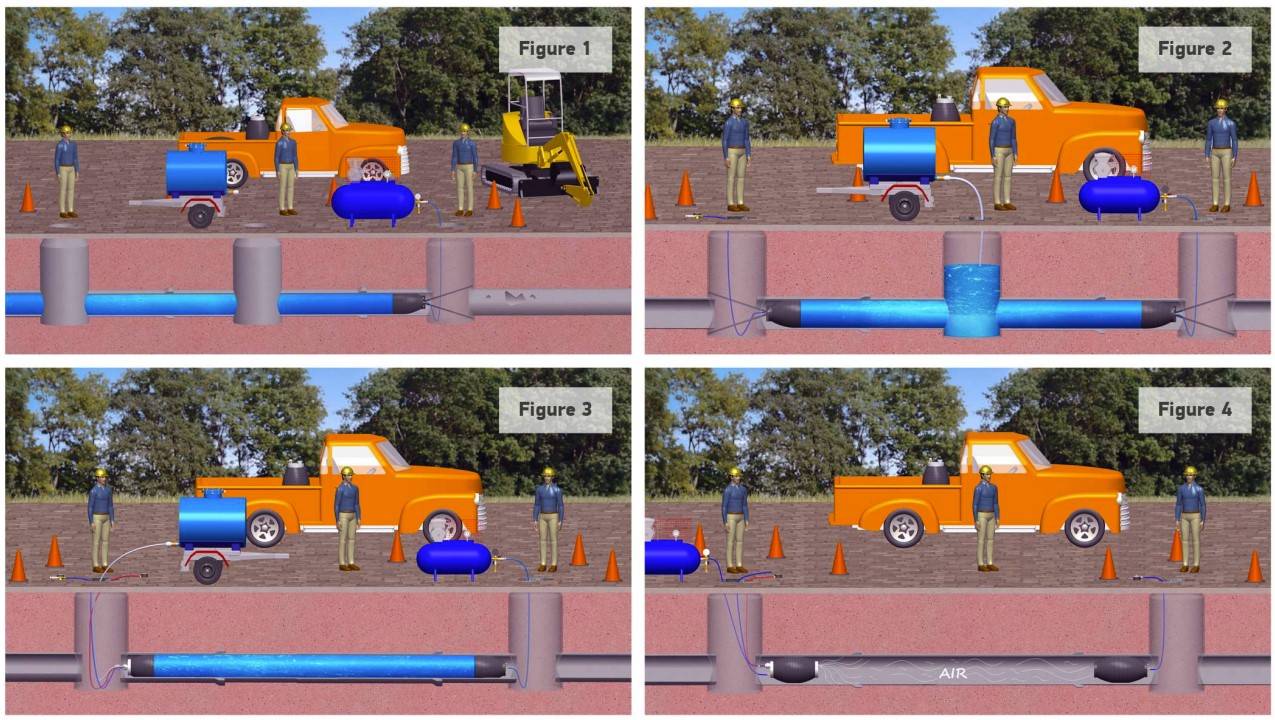

I. Temporary sealing or stopping the flow: Pipe plugs can be used for temporary blocking the flow in a pipeline (Figure-1) or to prevent the entry of dirt and other contaminants during construction, maintenance or repair of the pipeline.

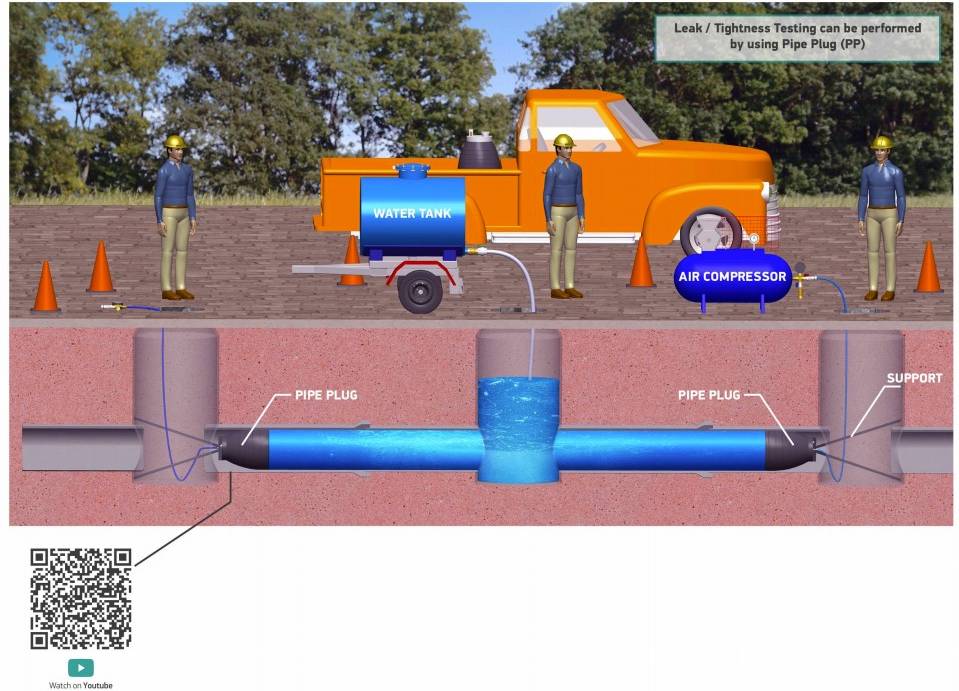

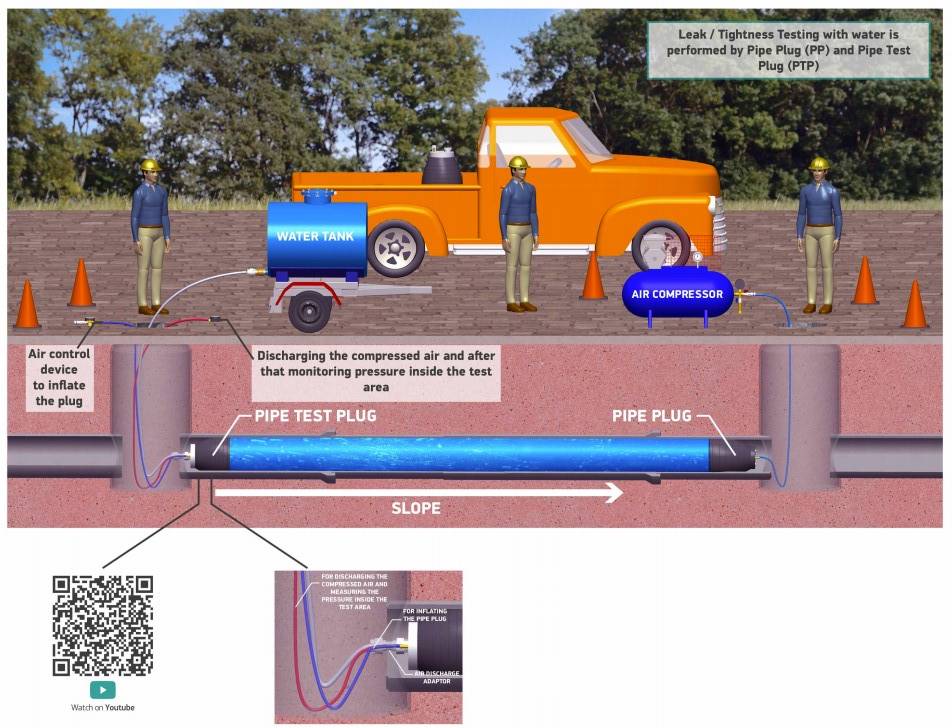

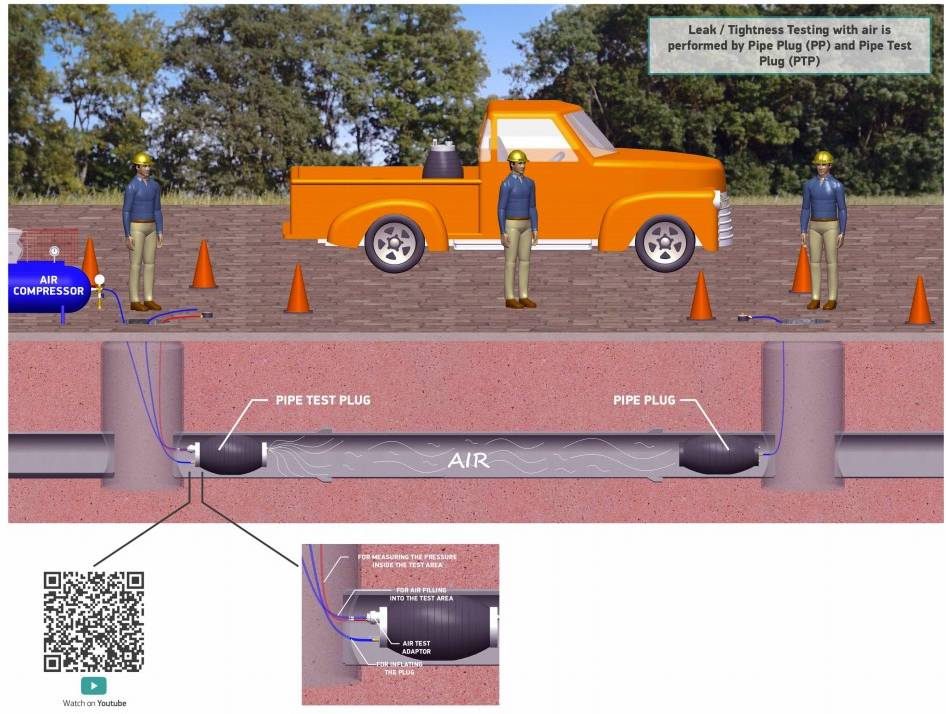

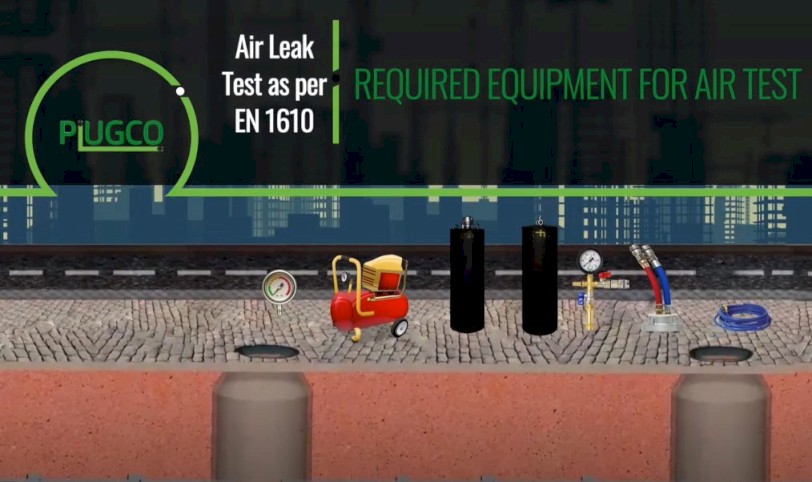

II. Testing: Leak/ tightness testing is performed by pipe plugs using water (Figure – 2 / 3) or air (Figure – 4).

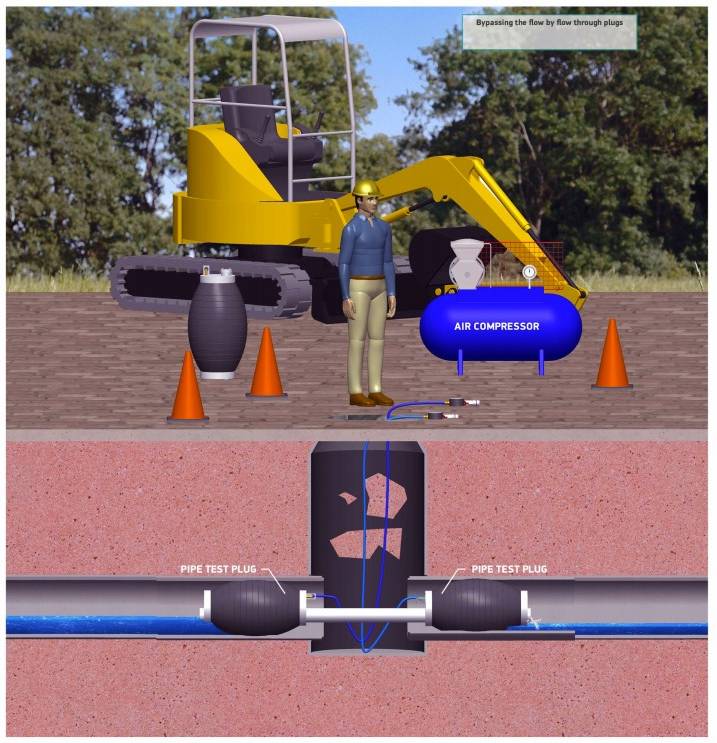

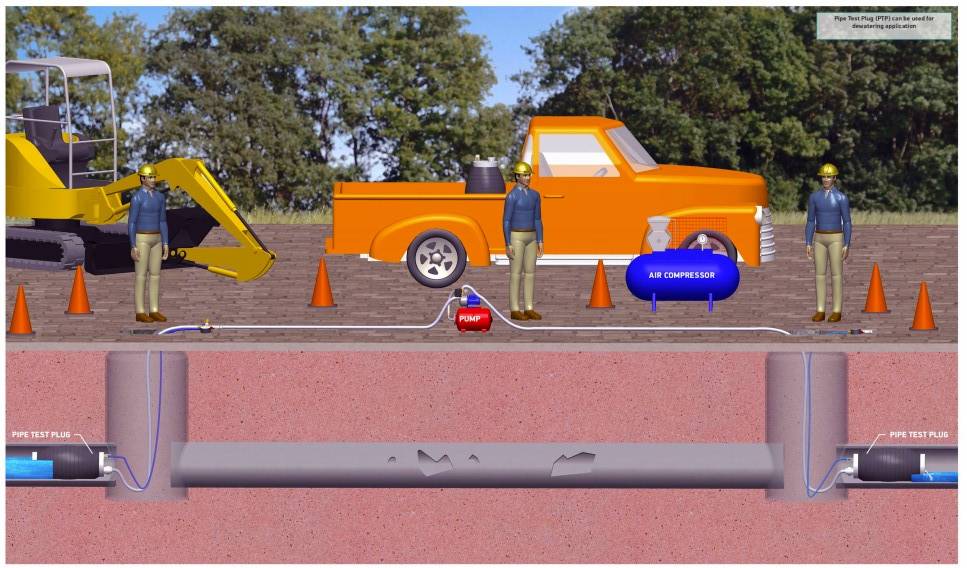

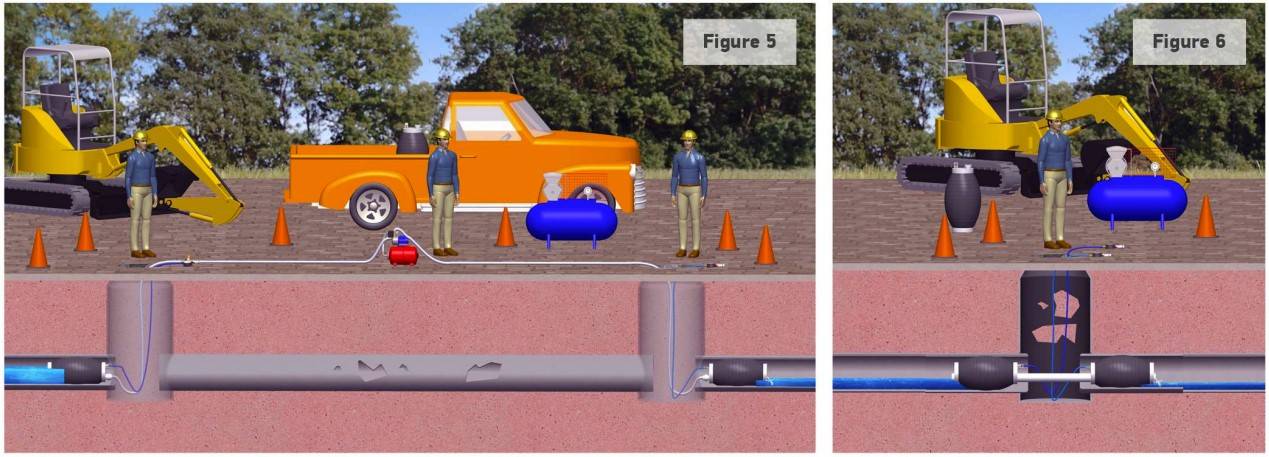

III. Bypassing the Flow: The Pipe Test Plugs can be used for dewatering application (Figure – 5) as well as for the flow deviation in a pipeline (Figure – 6).

INFLATABLE PIPE PLUG – Model PP

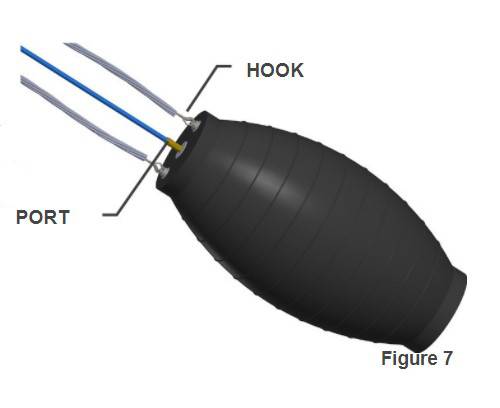

The main purpose of the pipe plug is blocking the pipelines or channels to stop flow temporarily. They can be also used for leak testing and repairing or maintenance of water, oil pipelines with different materials such as steel, plastic, HDPE etc. (Figure 7)

The main purpose of the pipe plug is blocking the pipelines or channels to stop flow temporarily. They can be also used for leak testing and repairing or maintenance of water, oil pipelines with different materials such as steel, plastic, HDPE etc. (Figure 7)

Pipe plug includes an inflation port for inflating the pipe plug and holding hooks for carrying. PlugCo can design the pipe plug with holding hooks on both sides as per the client’s requirement.

FLOW-THROUGH PIPE PLUG

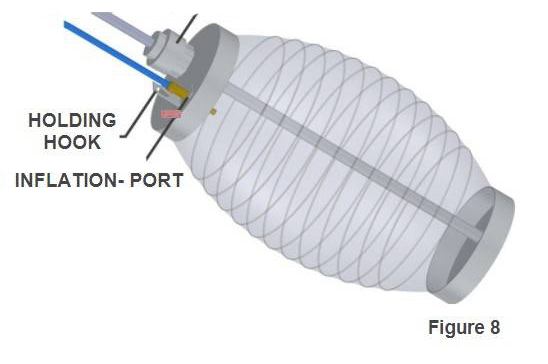

The Flow-through plug model is the same as the pipe plug model with the exception that it includes a bypass connection. The bypass connection allows water to fill inside the pipeline. It can also be used for bypassing the water flow and discharging it to another line and leak testing as well as de-watering or deviating the flow. (Figure 8)

The Flow-through plug model is the same as the pipe plug model with the exception that it includes a bypass connection. The bypass connection allows water to fill inside the pipeline. It can also be used for bypassing the water flow and discharging it to another line and leak testing as well as de-watering or deviating the flow. (Figure 8)

1.2 Safety Precautions Before Use

Before operation of pipe plug, the PlugCo Safety and User Manual must be carefully read and understand. Important safety rules and guidelines are outlined in this handbook.

Operators of pipe plug should be trained and authorized persons!

2. Selecting the Suitable PlugCo Pipe Plug

2.1 Back Pressure – Back Pressure Chart

Calculate the Back Pressure that the pipe plug must withstand before choosing the plug.

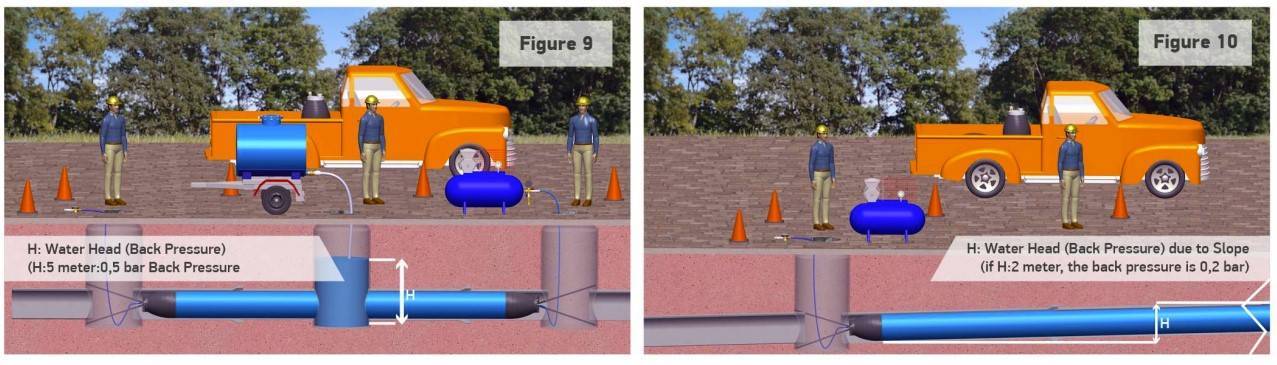

Back Pressure: The pressure of the fluid in a pipeline acting on the pneumatic plug sealing in the pipe. If there is only static pressure, It can be the elevation difference between the upstream and downstream ends of the pipe line. In other terms, the height of the water column behind the pipe plug (Figure – 9 / 10). For example, ten (10) meters water column behind the plug means 1 Bar Back Pressure. The surface area and shape of the water column are not important. Only the height of water column needs to be considered.

The specified back pressure on the technical data sheet is only valid for dry concrete pipe applications. Thus, we can recommend the Smart Plug, a product in our range, for any application where back pressure needs to be calculated regardless of the material or condition of the pipeline.

How to calculate the back-pressure force on the pipe plug:

- Measure the inner diameter (D) of the pipeline to be sealed by the pipe plug

- Calculate the surface area of the pipeline cross section (A)

- Calculate the total force that pipe plug must withstand from following equation (F)

F = P * A * 10 (N) A = π * D2 / 4 F = P * π * D2 / 4 * 10 (N)

A – Surface Area (cm2)

P – Back Pressure (bar)

D – Inner diameter of pipeline (cm) F – Total Force (N)

Example: The inner diameter of pipe= 500 mm. Water behind the pipe plug: 5-meter

F = P * A * 10 (N) A = π * D2 / 4

A = 3,14 * 252 / 4 = 490 cm2 F = 0,5 * 490 = 245 kg = 245 * 10 = 2450 N

BACK PRESSURE CHART

| PIPE DIAMETER mm / (inch) | ||||||||||||||||||||

| Pipe plug Code | 50 (2″) |

70 (2.75″) |

100 (4″) |

150 (6″) |

200 (8″) |

250 (10″) |

300 (12″) |

350 (14″) |

400 (16″) |

500 (20″) |

600 (24″) |

800 (32″) |

900 (36″) |

1000 (40″) |

1200 (48″) |

1400 (58″) |

1600 (64″) |

1800 (72″) |

2000 (80″) |

2200 (88″) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PP3570 (1,5 bar – 22 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

||||||||||||||||||

| PP50100 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||||

| PP50100 (2,5 bar – 37 psi) |

1,5 bar (22 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

|||||||||||||||||

| PP70150 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||||

| PP70150 (2,5 bar – 37 psi) |

1,7 bar (25 psi) |

1,4 bar (20,5 psi) |

1 bar (14,5 psi) |

|||||||||||||||||

| PP100200 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||||

| PP100200 (2,5 bar – 37 psi) |

1,7 bar (25psi) |

1,4 bar (20,5 psi) |

1 bar (14,5) |

|||||||||||||||||

| PP150300 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,7 bar (10 psi) |

0,5 bar (7,3 psi) |

||||||||||||||||

| PP150300 (2,5 bar – 37 psi) |

1,7 bar (25 psi) |

1,5 bar (22 psi) |

1,3 bar (19 psi) |

1 bar (14 psi) |

||||||||||||||||

| PP200400 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,7 bar (10 psi) |

0,5 bar (7,3 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||

| PP200400 (2,5 bar – 37 psi) |

1,7 bar (25 psi) |

1,5 bar (22 psi) |

1,3 bar (19 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

|||||||||||||||

| PP200500 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,9 bar (13 psi) |

0,8 bar (11,5 psi) |

0,7 bar (10 psi) |

0,6 bar (8,5 psi) |

0,5 bar (7,3 psi) |

||||||||||||||

| PP200500 (2,5 bar -37 psi) |

1,9 bar (27,5 psi) |

1,7 bar (25 psi) |

1,5 bar (22 psi) |

1,4 bar (20,5psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

||||||||||||||

| PP300600 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,7 bar (10 psi) |

0,6 bar (8,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||

| PP300600 (2,5 bar – 37 psi) |

1,5 bar (22 psi) |

1,4 bar (20,5 psi) |

1,3 bar (19 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

|||||||||||||||

| PP375800 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,9 bar (13 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

||||||||||||||||

| PP375800 (2,5 bar – 37 psi) |

1,9 bar (27,5 psi) |

1,7 bar (25 psi) |

1,5 bar (22 psi) |

1 bar (14,5 psi) |

||||||||||||||||

| PP5001000 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,7 bar (10 psi) |

0,6 bar (8,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||

| PP5001000 (2,5 bar – 37 psi) |

1,5 bar (22 psi) |

1,4 bar (20,5 psi) |

1,2 bar (17,5 psi) |

1,1 bar (16 psi) |

1 bar (14,5 psi) |

|||||||||||||||

| PP6001200 (1,5 bar – 22 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,7 bar (1O psi) |

0,6 bar (8,5 psi) |

0,5 bar (7,3 psi) |

|||||||||||||||

| PP6001200 (2,5 bar – 37 psi) |

2 bar (29 psi) |

1,6 bar (23 psi) |

1,3 bar (19 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

|||||||||||||||

| PP6001600 (1,0 bar – 14,5 psi) |

1,7 bar (25 psi) |

1,5 bar (22 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

0,3 bar (4,5 psi) |

|||||||||||||

| PP6001600 (1,5 bar -22 psi) |

2,3 bar (33 psi) |

1,8 bar (26 psi) |

1,5 bar (22 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

0,7 bar (10 psi) |

0,4 bar (6 psi) |

|||||||||||||

| PP8001600 (1,0 bar- 14,5 psi) |

2 bar ((29 psi) |

1,7 bar (25 psi) |

1,4 bar (20 psi) |

1 bar (14,5 psi) |

0,7 bar (10 psi) |

0,5 bar (7,3 psi) |

||||||||||||||

| PP8001800 (1,0 bar – 14,5 psi) |

2,3 bar (33 psi) |

1,7 bar (25 psi) |

1,4 bar (20 psi) |

1,2 bar (17,5 psi) |

1 bar (14,5 psi) |

0,7 bar (10 psi) |

0,4 bar (6 psi) |

|||||||||||||

| PP8002000 (1,0 bar – 14,5 psi) |

2,6 bar (37,5 psi) |

2,3 bar (33 psi) |

2 bar ((29 psi) |

1,5 bar (22 psi) |

1,2 bar (17,5 psi) |

0,8 bar (11,5 psi) |

0,5 bar (7,3 psi) |

0,4 bar (6 psi) |

||||||||||||

| PP8002200 (1,0 bar – 14,5 psi) |

2,9 bar (42 psi) |

2,7 bar (40 psi) |

2,5 bar (36 psi) |

2 bar ((29 psi) |

1,5 bar (22 psi) |

1 bar (14,5 psi) |

0,6 bar (8,5 psi) |

0,5 bar (7,3 psi) |

0,4 bar (6 psi) |

|||||||||||

THIS TABLE ONLY INCLUDES 1,0 1,5 BAR AND 2,5 BAR INFLATING (WORKING) PRESSURE.

CONSULT PLUGCO FOR OTHER WORKING PRESSURES. THIS IS ONLY APPLICABLE FOR DRY CONCRETE PIPES.

2.2 Temperature Effect

Determine the temperature that the plug will be exposed to.

The environmental temperature should not exceed 70 degree Celsius for SBR + NR mixed rubber and 60 degree Celsius for CR (Neoprene) Rubber. Heat can damage the pipe plug permanently.

The lowest temperature at which the pipe plugs maintain their sealing characteristic in the pipeline is -20 degree Celsius for both SBR + NR mixed and CR Rubber.

2.3 Diameter of Pipeline, Access Opening and Pipe Shape

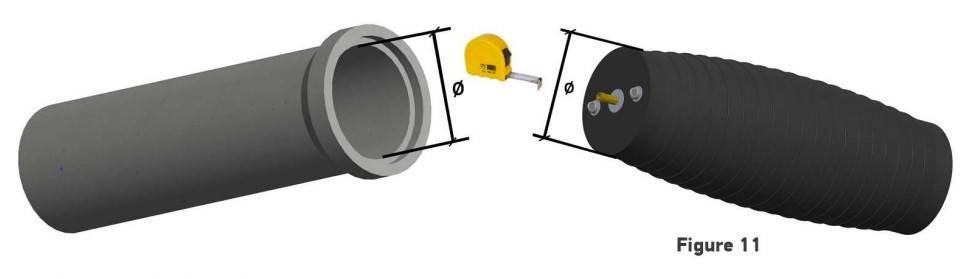

Before operation, always measure the inner diameter of pipeline, in which the plug will be inserted, and make sure that pipe diameter is within the range specified on the plug (Figure – 11). The maximum and minimum allowable pipe diameter are marked on every inflatable pipe plug.

There are two situations that annoy the choice of plug.

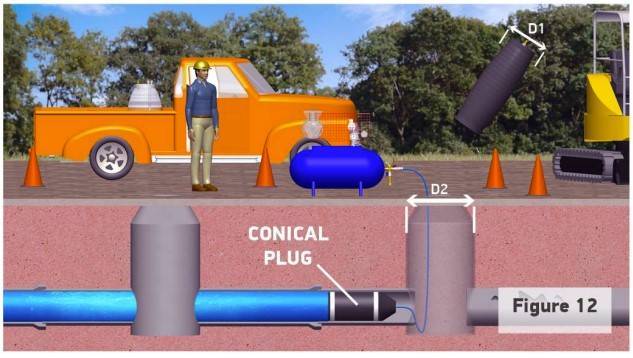

1. Access opening: Underground and industrial piping does not always having equal-sized access point which is limiting the choice of the suitable pipe plug. (Figure-12) So be sure that the diameter of the access opening where the plug will be inserted .

D1: Deflated Diameter of Pipe Plug

D1: Deflated Diameter of Pipe Plug

D2: Diameter of Manhole

D1>D2

2. Pipe Shape: The pipe plugs can only be used for cylindrical pipes. Define the shape of the pipe where the plug will be used.

If case the access opening is limited and/or the shape is not cylindrical (Egg, square … etc), PlugCo advices to use the Conical Plug which is suitable for this kind of applications

2.4 Chemical Resistance Table for Rubber Material

Check the chemical resistance table for rubber material and consider it while selecting the pipe plug or consult the manufacturer.

Rubber types of Plugco pneumatic plugs with regard to their resistance to chemicals

| Media | Temperature (C) | SBR/NR | CR | NBR |

|---|---|---|---|---|

| Acetone | 23 | 1 | 2 | 4 |

| Acetylene | – | 1 | 2 | 1 |

| Ammonium hydroxide | 23 | 1 | 1 | 1 |

| Aniline | 23 | 2 | 3 | 4 |

| Aniline | 100 | 4 | 4 | 4 |

| Benzene | 23 | 4 | 4 | 4 |

| Boric acid | 100 | 1 | 1 | 1 |

| Brake fluid (vegetable) | 50 | 1 | 1 | 4 |

| Butanol | 50 | 1 | 1 | 1 |

| Butanol | 100 | 4 | 3 | 1 |

| Butyric acid | – | 2 | 4 | |

| Calcium hydroxide | 100 | 1 | 1 | 2 |

| Calcium hypochlorite | 4 | 2 | 3 | |

| Chloric acid | 23 | – | 4 | 4 |

| Ethanol | 50 | 1 | 1 | 1 |

| Ether | 23 | 4 | 4 | 2 |

| Formaldehyde | 23 | 1 | 1 | 1 |

| Glycerine | 100 | 1 | 1 | 1 |

| Hexanol | 23 | 1 | 2 | 2 |

| Hydrogen peroxide | 23 | 1 | 1 | 1 |

| Kerosene | 70 | 4 | 3 | 1 |

| Methanol | 50 | 1 | 1 | 1 |

| Methyl chloride | – | 4 | 4 | 4 |

| Milk | 23 | 1 | 1 | 1 |

| Oil 1 (ASTM No.1, ISO 1817) | 100 | 4 | 1 | 1 |

| Oil 2 (IRM 902, ISO 1817) | 100 | 4 | 2 | 1 |

| Oil 3 (IRM 903, ISO 1817) | 100 | 4 | 4 | 1 |

| Naphtha | 23 | 4 | 4 | 1 |

| Natural gas | – | 3 | 1 | 1 |

| Nitric acid (diluted) | 50 | 2 | 3 | 2 |

| Ozone (conc. 50 pphm) | 40 | 4 | 2 | 4 |

| Phenol | 100 | 4 | 4 | 4 |

| Phosphoric acid | 50 | 2 | 2 | 3 |

| Propanol | 50 | 1 | 1 | 2 |

| Sodium hydroxide-Concentration %10 | 100 | 1 | 1 | 1 |

| Sodium hydroxide-Concentration %25 | 100 | 1 | 1 | 4 |

| Sodium hypochlorite | 50 | 2 | 3 | 3 |

| Sulphur hexafluoride | 1 | 1 | ||

| Sulphuric acid (VI) – Concentration %10 | 100 | 1 | 1 | 3 |

| Sulphuric acid (VI) – Concentration %20 | 23 | 1 | 1 | 3 |

| Sulphuric acid (VI) – Concentration %25 | 100 | 1 | 1 | 4 |

| Sulphuric acid (VI) – Concentration %50 | 100 | 1 | 1 | 4 |

| Sulphuric acid (VI) – Concentration %60 | 100 | 3 | 4 | 4 |

| Sulphuric acid (VI) – Concentration %75 | 100 | 4 | 4 | 4 |

| Toluene | 23 | 4 | 4 | 4 |

| Toluene | 23 | 4 | 4 | 4 |

| Sulphuric acid (VI) – Concentration %96 | 23 | 4 | 4 | 4 |

| Toluene | 23 | 4 | 4 | 4 |

| 1- NEGLIGIBLE | 2- LOW | 3- MEDIUM | 1- SIGNIFICANT |

|---|

If the media to be used is not in this table, please check the standard ISO/TR 7620, or consult the manufacturer about the usage of Plugco Inflatable pipe plug.

3. Reception of Pipe Plug

(Removing Package – Inspection-Storage)

• Removing the Package: Do not use the sharp items such as knife, screwdrivers and similar, for removing the packing, since they can damage the pipe plug.

Note: Only exceptionally the pipe plug may be under the vacuum during the transportation. Once received, immediately release the vacuum. Insert the air into the plug until it reaches the original cylindrical form.

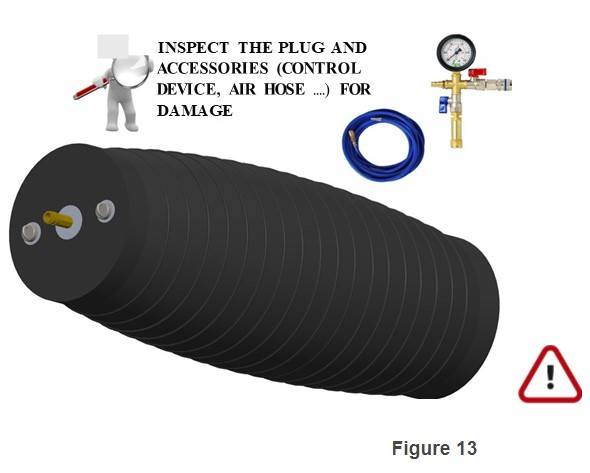

• Inspection: Inspect the plug and related equipment (control device, air hose….) for damage before and after each use. (Figure -13)

Inflate the pipe plug up to 0.1 bar and check the connection points on the plug by using the soapy water or immerse the pipe plug fully in water. The leaks, if any, will cause the soap bubbles. Look very carefully for evidence if any part of the pipe plug has been damaged, weakened or missing.

Inflate the pipe plug up to 0.1 bar and check the connection points on the plug by using the soapy water or immerse the pipe plug fully in water. The leaks, if any, will cause the soap bubbles. Look very carefully for evidence if any part of the pipe plug has been damaged, weakened or missing.

Visually inspect the accessories (control device, air hose …).

And also, they can be inspected in the same way as pipe plug by using the soapy water.

WARNING!! Do not use the pipe plug if it has or shows any signs of wear or deterioration and contact PlugCo team.

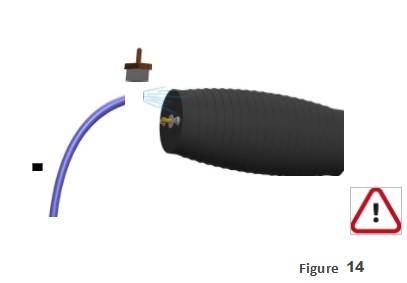

– At first reception and before/after each use, clean the pipe plug with a solution of water and detergent (Figure – 14). After cleaning, flush the pipe plug with clean water and allow it to dry thoroughly before using.

– At first reception and before/after each use, clean the pipe plug with a solution of water and detergent (Figure – 14). After cleaning, flush the pipe plug with clean water and allow it to dry thoroughly before using.

– Storage: Cleaned plug can be stored suspended vertically or placed horizontally and in dry and dark space at temperature between 15 ® 25-degree Celcius.

It should be free from sharp edges and should not touch steel or concrete floor directly. Wood palets is suitable for plugs stand on

WARNING!! Do not clean the pipe plug with solvent or petroleum fluids which may damage the pipe plug!

Never use solvent, hydrocarbon and other aggressive substances for cleaning the PlugCo pipe plug. The use of such substances can damage or even destroy the pipe plug.

4. Application Procedure of Pipe Plug

4.1 Protective Equipment and Safety

◦ Use and wear related safety and protective equipment.

◦ Use and wear related safety and protective equipment.

◦ Before entering the manhole or confined space, thoroughly check for hazardous gasses and proper oxygen levels. If necessary, ventilate the confined space. Strictly follow the confined space safety procedures.

4.2 Insertion of pipe plug in a pipe

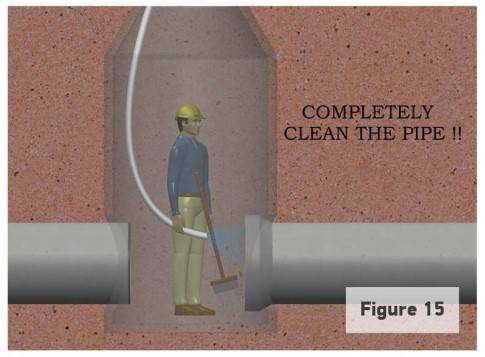

• Before inserting the pipe plugs properly clean the interior of pipeline:

Clean the pipe from any debris or foreign substances (Figure – 15) which may reduce the back pressure holding capability before the pipe plug is installed. Foreign substances may include grass, oil, mold or any other material that can prevent solid contact between the pipe plug and pipe wall.

Clean the pipe from any debris or foreign substances (Figure – 15) which may reduce the back pressure holding capability before the pipe plug is installed. Foreign substances may include grass, oil, mold or any other material that can prevent solid contact between the pipe plug and pipe wall.

A clean contact surface of pipeline increases the pipe plug quality in sealing as well as in holding more back pressure.

Warning!! Failure to clean the pipe properly may result in pipe plug dislodgement or pipe plug failure causing death, serious bodily injury or property damage!

• The inflation hose must be of enough length to inflate or deflate the pipe plug from outside the Danger Zone.

• Insert the plug into the pipeline

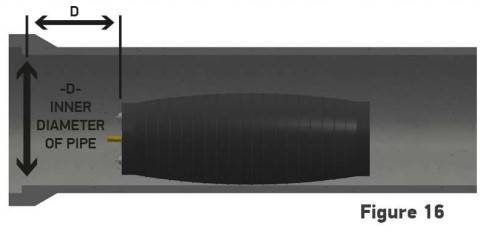

Before inflating the pipe plug, position it correctly in the pipeline. The shortest allowable distance from the beginning of the pipeline to the pipe plug is equal to the pipeline diameter. (Figure 16)

Before inflating the pipe plug, position it correctly in the pipeline. The shortest allowable distance from the beginning of the pipeline to the pipe plug is equal to the pipeline diameter. (Figure 16)

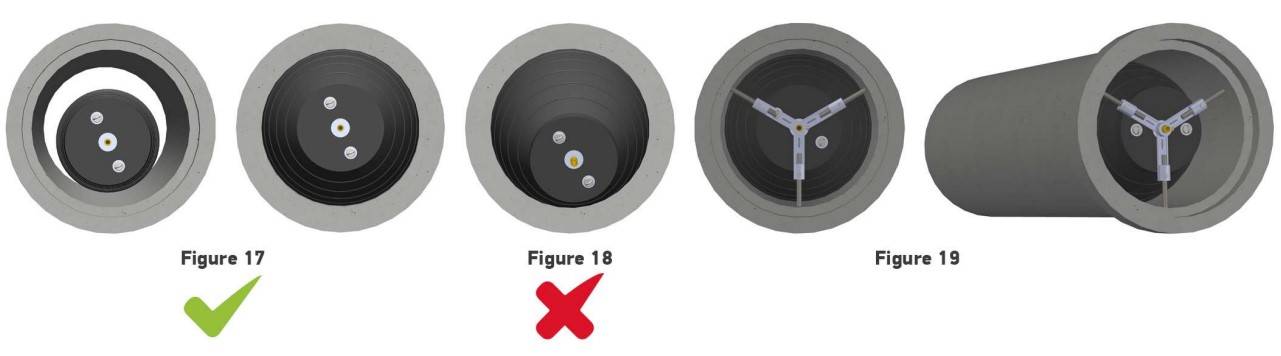

The pipe plug must be positioned horizontally and it must be centralized in the middle of pipe’s cross-section (Figure -17 /18)

If the pipe plug is inserted incorrectly, this could cause incorrect distribution of forces inside the plug and also not homogeneous sealing between pipe plug and pipe wall and consequently permanent damage of the pipe plug as well as lower back pressure held. Plugco recommend to use the Plugco Centralizer to a safe and easy centerizing of the plug (Figure -19).

4.3 Dangerous Zone

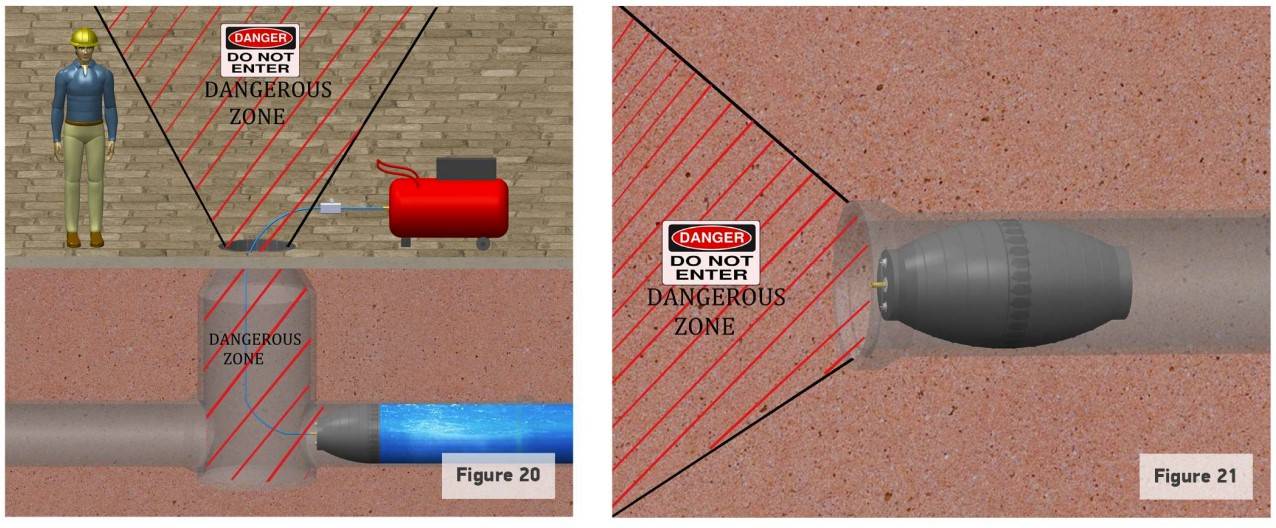

Never allow a person to enter the test area (DANGER ZONE) when pipe plug is inflated in the pipe (Figure – 20-21)

WARNING! All inflatable products have a risk of suddenly rupturing. Pipe plug failure for any reason may result in deat h, serious bodily injury and/or property damage! Do not enter the Danger Zone when the pipe plug is under pressure!

Dangerous Zone is the most critical subject for plug usage. Therefore, all workers should be informed about the Dangerous Zone in the application. Project safety person should take necessary action to avoid the workers enter the Dangerous Zone.

4.4 Connection of Accessories on the Plug

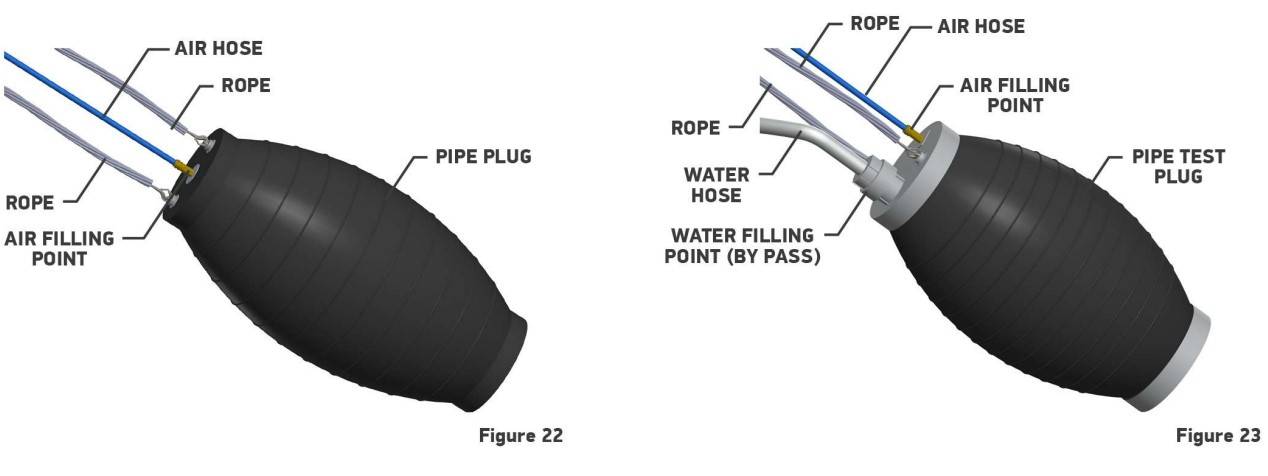

• Attach the air hose to inflation connection, the anchor hook(s) to eyebolt(s) and the water hose to its connection for filling the test area with water. All hoses have universal quick release connection.

• Check the air hose, water hose, chain, rope and their connections to make sure that they are not damaged or leaking before the operation. (Figure – 22 ® 23)

4. 5 Supporting The Pipe Plug

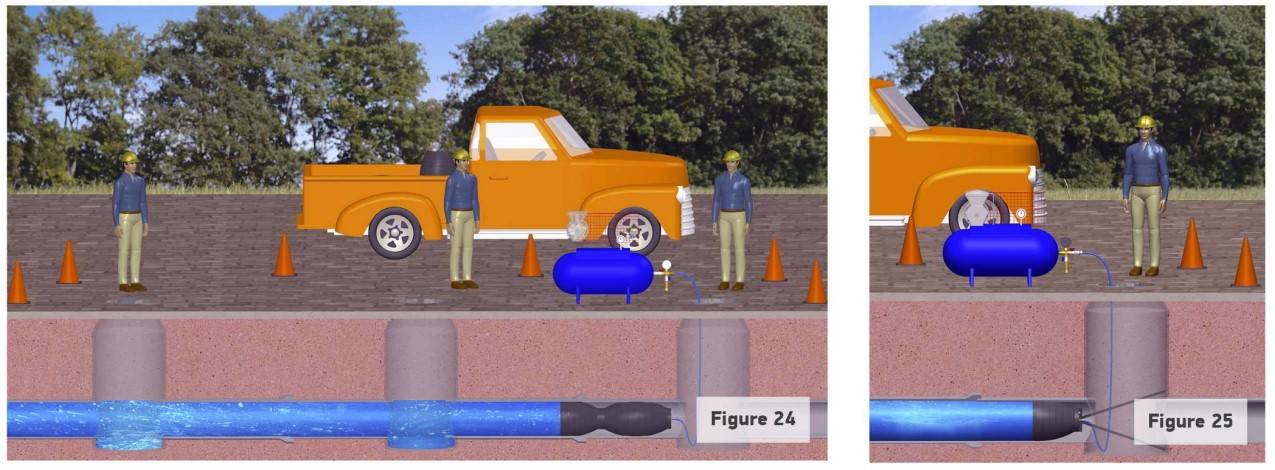

• Proper support or bracing must be mounted to secure the pipe plug in place. Bracing support should contact the front face of the plug and the contact surface should be smooth to distribute forces equally on the pipe plug. Sharp points of contact may damage the pipe plug. (Figure – 24 ® 25)

• The end user should calculate the back forces and design suitable supports to prevent sliding of the plug.

Warning!! Pipe Plugs under pressure must be braced. Always brace the pipe plug securely!

Warning!! Never use eyebolts or handles on pneumatic plugs for fixing, of safety supports, since these are intended solely for lowering and lifting pipe plugs.

4.6 Inflation of the Pipe Plug

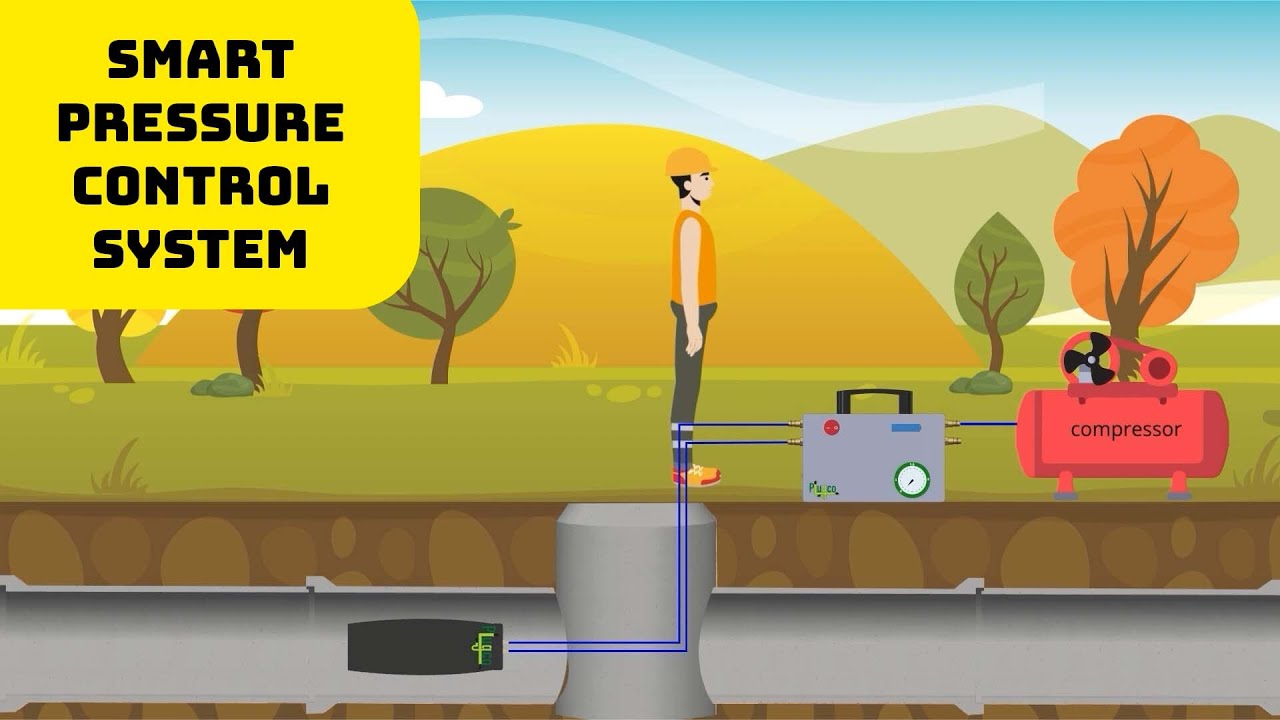

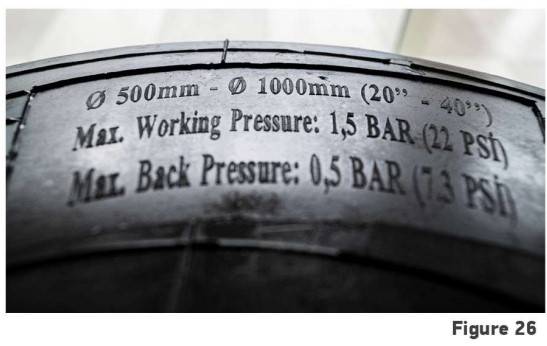

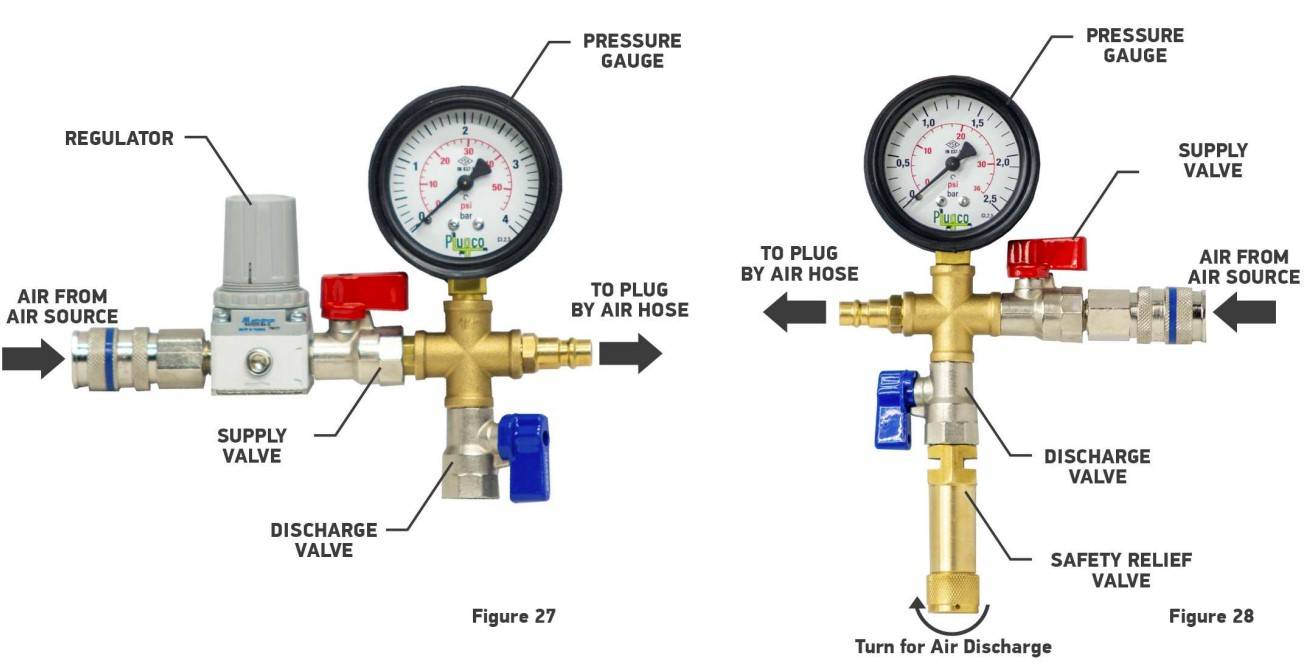

• ALWAYS inflate the pipe plug up to the max. allowable inflation pressure (working pressure) marked at the technical data sheet and on the pipe plug (Figure 26).During pipe plug inflation, monitor the pressure closely on the control device.

• ALWAYS inflate the pipe plug up to the max. allowable inflation pressure (working pressure) marked at the technical data sheet and on the pipe plug (Figure 26).During pipe plug inflation, monitor the pressure closely on the control device.

WARNING!! NEVER exceed the inflating pressure value outlined in the PlugCo Catalog and marked on the pipe plug. Also do not apply less inflation pressure than the Max. Inflation Pressure. Always inflate exactly Max. Inflation Pressure.

Recommendation: Since air is compressible, it is often advisable to inflate larger diameter pipe plugs with water.

• The inflation should be done from a location outside of the Danger Zone using an inflation hose, a proper pressure source and a calibrated control device to monitor the working pressure.

• Check the inflation pressure on the control device regularly. A small volume of inflation air leaks through the elastomeric body of every inflatable pipe plug. This lost air must be replaced periodically.

The control device should be connected to the plug throughout the inflation of the pneumatic plug and also during the period under the pressure. If the permissible working pressure is exceeded, safety valve is activated and begin to reduce the pressure in the pipe plug.

When activated, the flow volume of the safety relief valve is limited. In the case of air source with high flow capacit y, it can happen that the activated safety valve does not completely interrupt inflation of pipe plug but only slows it down.

The activated safety valve has a characteristic of loud sound. Upon activation of safety relief valve the operator must immediately close the supply valve on the controller to interrupt inflation of the pipe plug.

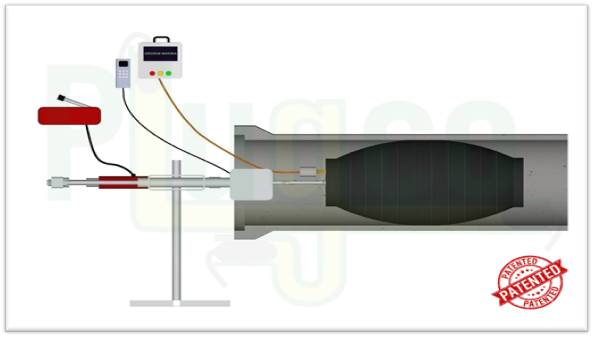

For advance pressure monitoring we recommend to use PlugCo Pressure Monitoring and Alarm System. (Figure 29)

The conditions where plug should not be inflated;

The conditions where plug should not be inflated;

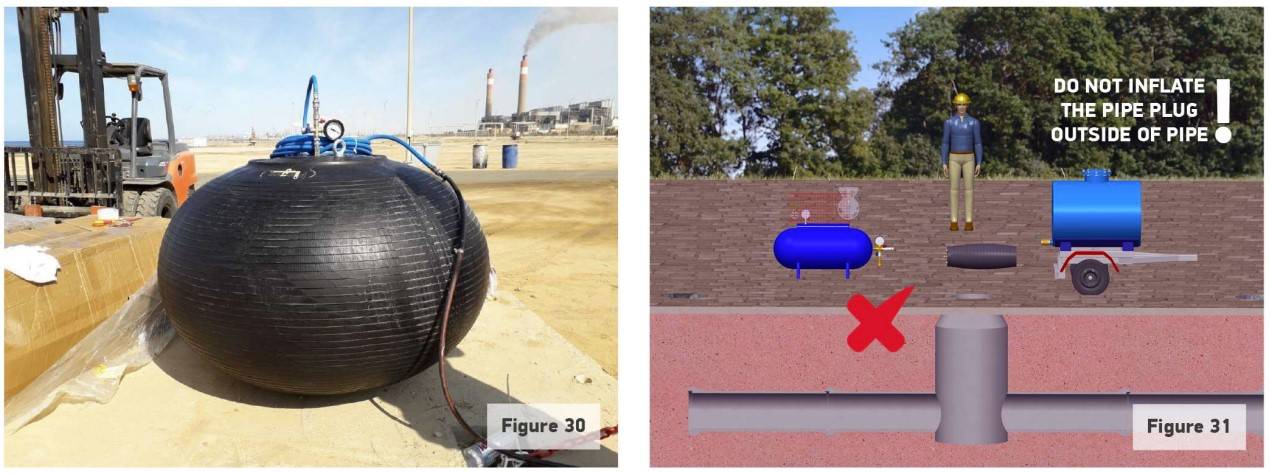

• Never inflate the pipe plug outside of the pipe (Figure – 30 ® 31).

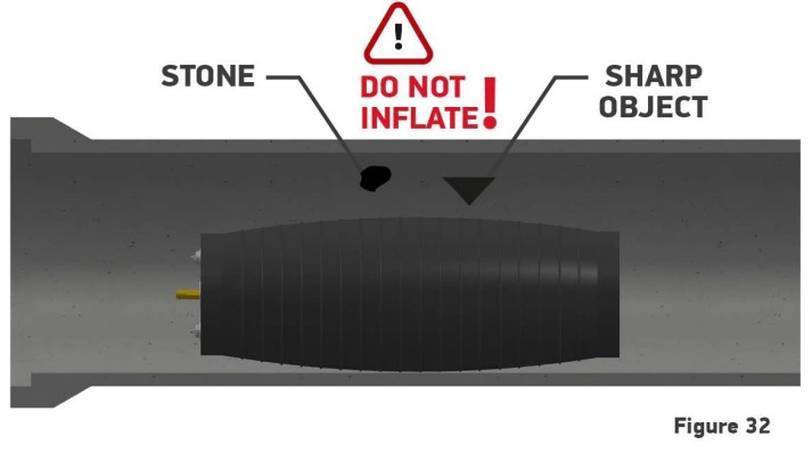

• Never inflate the pipe plug over or near sharp objects (Figure 32). Remove all sharp objects, stones and any foreign material from the pipe before inserting the pipe plug.

• Never inflate the pipe plug over or near sharp objects (Figure 32). Remove all sharp objects, stones and any foreign material from the pipe before inserting the pipe plug.

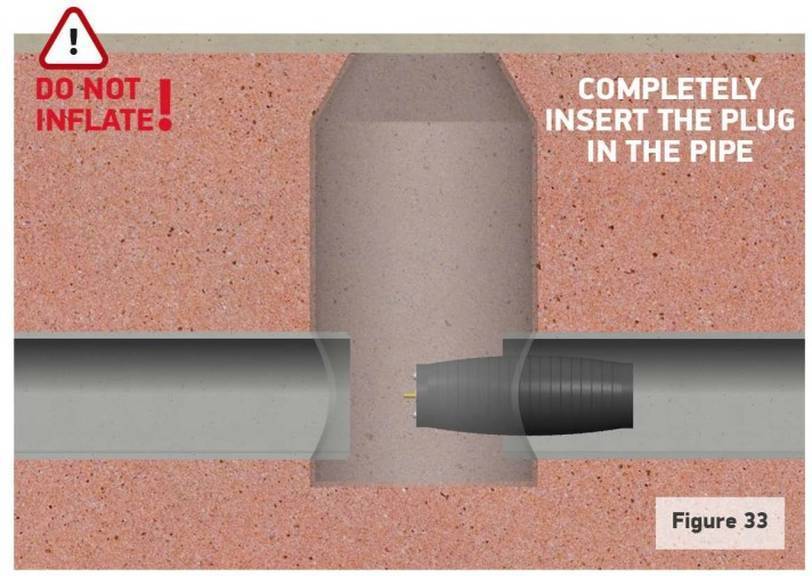

• Never allow the pipe plug to protrude from the end of the pipeline during inflation or use. Always completely insert the plug into the pipe line. (Figure – 33)

• Never allow the pipe plug to protrude from the end of the pipeline during inflation or use. Always completely insert the plug into the pipe line. (Figure – 33)

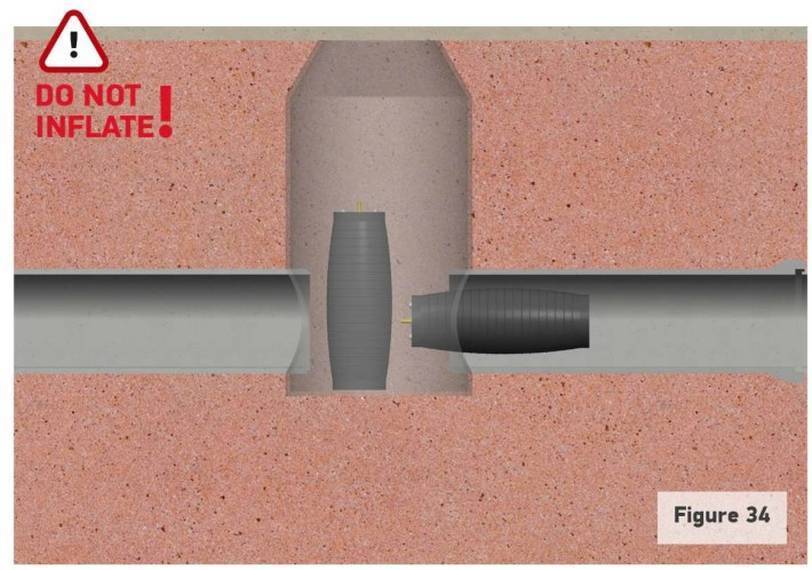

• Never inflate the pipe plug over laterals or other openings. (Figure – 34)

• Never inflate the pipe plug over laterals or other openings. (Figure – 34)

5. Procedure of After Testing

• After completing the test/application, release the back pressure (head pressure) completely. Then open the discharge valve and deflate the pipe plug. Release the air in the pipe plug from outside the Danger Zone through the inflation hose until the pipe plug is completely deflated.

How to release the back pressure

• By pumping the water behind the plug

• Open the safety valve/discharge valve on the controller to release the working pressure until pressure gauge shows zero

• Never remove the pipe plug from the pipeline until all pipeline back pressure is released and the pipe plug is deflated.

• Never remove the pipe plug from the pipeline until all pipeline back pressure is released and the pipe plug is deflated.

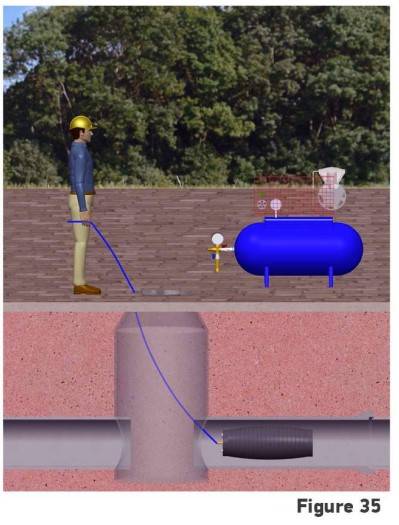

• Never use the air inflating hose to remove the pipe plug from the pipe. Use chain or cable to install and remove the pipe plug. (Figure – 35)

• After using the inflatable pipe plug, clean it with detergent/water and inspect the plug for damage, tears or any other defect.

6. Storage

• Store the cleaned pipe plug in a clean dry place at room temperature and away from direct sunlight as per IS02230.

IS02230 list of instructions:

– Store at temperature between 15-25-degree Celcius

– Store in dry storage space

– Screen it from direct (sun) light

– Screen it from circulating air.

– As far as possible, ensure that pipe plug is not subjected to pressure while stored.

– Avoid long-term contact with liquid during storage.

– Avoid long-term contact with metals during storage.

– Avoid long-term contact with other rubber during storage.

– After long-term storage, the pipe plug can be cleaned with soap and water. Once cleaned, it should be left to dry at room temperature.

• Pipe plug must be stored suspended vertically or placed horizontally.

7. Warranty

Manufacturer warrants that all pneumatic plugs manufactured by it and shown in this manual will be free from defects in material and workmanship for one

(1) year following the date of manufacture. If any of the goods are found to be defective, such goods will, at manufacturer’s option be replaced or repaired at manufacturer’s cost. The parties hereto expressly agree that buyer’s sole and exclusive remedy against the manufacturer shall be for the repair and/or replacement of defective goods as provided herein. (The sole purpose of the stipulated exclusive remedy shall be to provide the buyer with free repair and replacement of defective goods in the manner provided herein. The exclusive remedy shall not be deemed to have failed of its essential purpose so long as the manufacturer is willing and able to repair or replace defective goods in the prescribed manner.) Goods which may be sold by manufacturer but are not manufactured by it are not warranted by manufacturer, but are sold only with the warranties, if any, of the original manufacturers thereof.

(This warranty does not cover labor or other costs or expenses to remove or install any defective, repaired or replaced goods.) Manufacturer’s warranty does

not apply to any goods which have been subjected to misuse, mishandling, misapplication, neglect (including but not limited to use of unauthorized parts or attachments), or adjustment or repair performed by anyone other than manufacturer or one of manufacturer’s authorized agents.

Any claim by buyer with reference to the goods sold hereunder shall be deemed waived by the buyer unless submitted in writing to manufacturer within the earlier of (1) thirty (30) days following the date buyer discovered or by reasonable inspection should have discovered, any claimed breach of the foregoing warranty, or (2) twenty-five (25) months following the date of manufacture. Any cause of action for breach of the foregoing warranty shall be brought within one year from the date the alleged breach was discovered or should have been discovered, whichever comes first. LIMITATION OF LIABILITY. Manufacturer’s liability (whether under the theories of breach of contract or warranty, negligence, or strict liability) for its goods shall be limited to repairing or replacing parts found by the manufacturer to be defective, or at manufacturer’s option, to refunding the purchase price of such goods or parts thereof.

DISCLAIMER OF CONSEQUENTIAL DAMAGES. In no event shall manufacturer be liable for consequential damages arising out of or in connection with this agreement, including without limitation breach of any obligation imposed on manufacturer hereunder or in connection herewith. Consequential damages for purposes hereof shall include, without limitation (including death) to any person, or loss or damage to property (including without limitation property handled or processed by the use of the goods). Buyer shall indemnify manufacturer against all liability, cost or expense which may be sustained by manufacturer on account of any such loss, damage or injury.

DEFECTIVE PRODUCTS POLICY. To obtain performance under this warranty, any product suspected of having a manufacturing defect in materials or workmanship at manufacturers request must be returned to PLUGCO INDUSTRIES INCORPORATED, freight prepaid, for inspection. A returned goods authorization (RGA) must be obtained before shipping any product back to PLUGCO. Contact (sales@plugco.net)

CUSTOMER TRANSPORTATION REIMBURSEMENT. Whenever PLUGCO repairs or replaces a product at PLUGCO’S expense, PLUGCO will reimburse the distributor by credit memo, the same surface freight amount it cost PLUGCO to return the warranty items.

The foregoing warranty is in lieu of all other warranties express or implied, including those of merchantability or fitness for any purpose not expressly set forth herein. No affirmation of manufacturer, by words or action, other than as set forth in this language shall constitute a warranty.

8. Application Drawings of the Pipe Plug/Pipe Test Plug