Pipe Plug Supplier

As Pipe Plug Supplier, PlugCo produces a variety of pipe test equipment. PlugCo is one of the biggest pipe plug manufacturers globally, as we export our products to more than 60 countries.

PlugCo Wholesale Pipe Plugs

Wholesale pipe plugs produced by PlugCo are used for different projects all over the world. Check our Latest Videos, News, Blogs, and Case Studies!

Pipe Plug Company Details

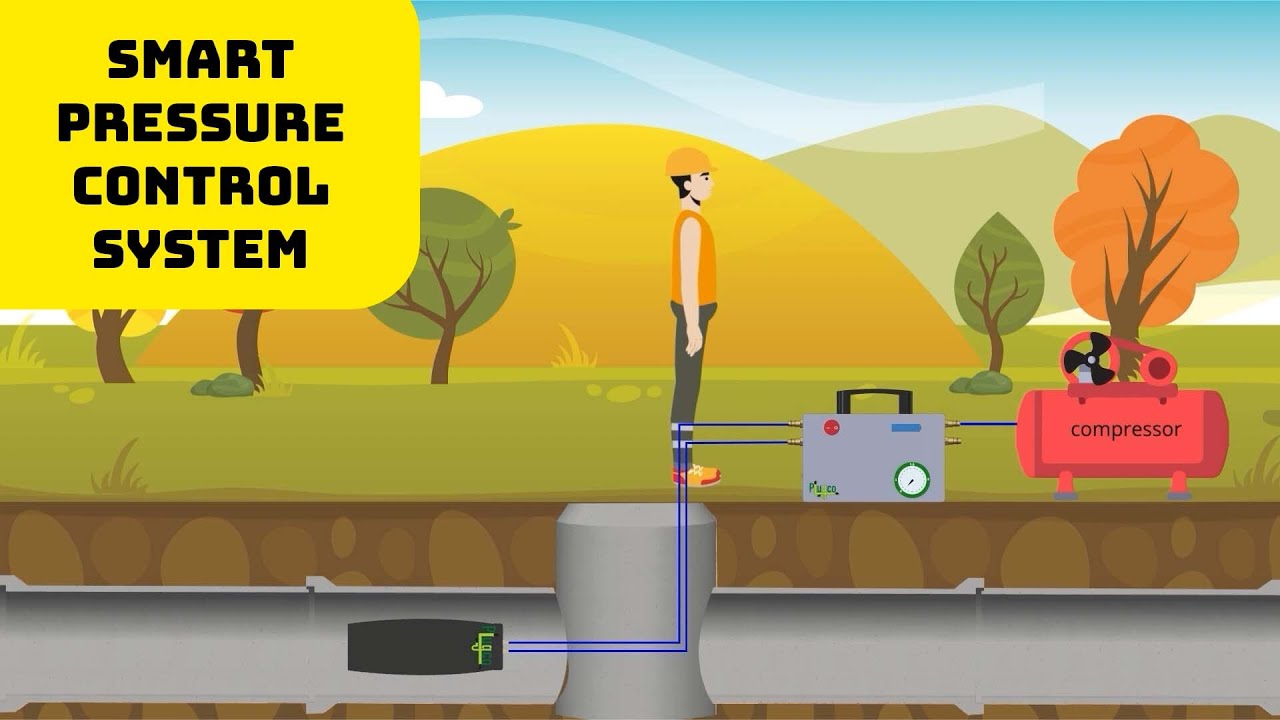

Many storm drainage-pipelines, sanitary sewer lines, and low-pressure underground pipelines do not have valves or spectacle flanges to block fluid flow in the line. PlugCo, a pipe plug company, has the answer to this dilemma! By easily blocking these lines and permitting access to them without the need for expensive, maintenance-intensive valves and flanges! So that the pipeline becomes accessible for inspection, maintenance, or modification.

PlugCo, one of the biggest pipe plug manufacturers, has an extensive range of pipe sealing and pipe repair products, including many designs of inflatable stoppers, joint testers, and pillow packers.

Pipe Plug Models

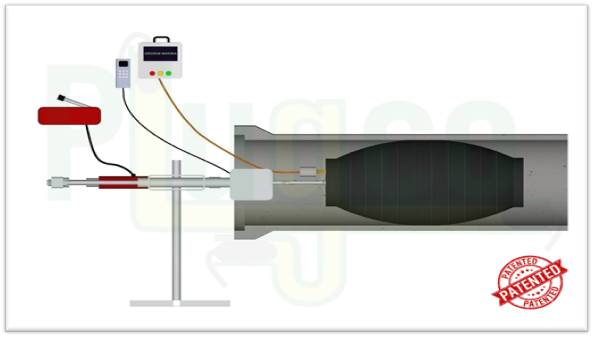

PlugCo produces inflatable pipe plugs in sizes from 35mm (1.4 inches) to 3600mm (144 inches) in diameter. These plugs’ designs fit into three broad categories — cylindrical single-size plugs, cylindrical multi-size plugs, and conical plugs.

The conical pipe plug, although more expensive, has several advantages over a cylindrical plug design. Conical pipe plugs are manufactured in larger sizes than cylindrical plugs – up to 3600mm (144in / 12ft) in diameter. The most significant difference between the two designs, however, is that a conical pipe plug can be folded to a small diameter, which can be easily inserted into a narrow or constricted opening. Therefore, in many cases, this advantage means that a manhole does not need be removed or be located near the location where a conical plug is to be inserted or inflated.

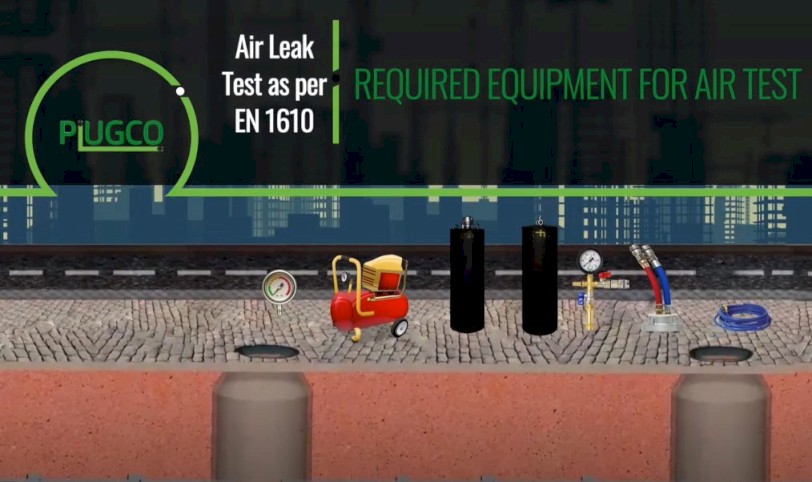

In addition to its extensive product line of pipe plugs and conical plugs, PlugCo has products to test individual pipe joints. By testing a single pipe joint only, these joint testers have low water consumption. In other words, this means lower testing costs and reduced environmental impact.

PlugCo: a Pipe Packer Supplier

In addition to previously mentioned models, we also manufacture flexible pipe packers, which are used for point repairs of sewer, drainage, and water lines. These products provide a no-dig, trenchless solution for pipe repairing that will be attractive to both utilities and contractors. A straight — or lateral — packer is for repairing straight lines, and a “bendy” packer is used for repairing 45- and 90-degree elbows. PlugCo also provides pillow packers for point repair of large pipe sizes. Pillow packers, like the conical pipe plugs, can easily fit through narrow or constricted openings.

Special Products for Different Pipeline Applications

We have also developed and manufactured a special stainless-steel plug for Cured-In-Place Pipe (CIPP) repairs, called a steam process plug. This plug uses process steam to accelerate the curing process, and the SS construction is significantly different from other CIPP plugs in the marketplace.

PlugCo is not only a manufacturer of plugs mainly serving the “water infrastructure” industry — sewer, storm drains, and potable water pipelines — it is also a supplier for plugs used for sealing hydrocarbon lines such as oil, petrol, and natural gas. Our nitrile rubber gas plugs provide excellent resistance against petrochemical fluids. PlugCo produces gas plugs capable of withstanding up to 8 bar pressure for Pig applications in oil and gas lines. In the same context, PlugCo supplied Gas & Oil Plug Models with Bypass connection for a well-known Oman company after our engineer had visited them and given them a training on how to use our pipe plugs.

PlugCo at Your Service

PlugCo is considered one of the most reliable pipe plug suppliers as our entire team is at your full service to meet your unique needs. Custom products are always available. Our engineers, designers, technicians, and fabricators look forward to working with you on your specific requirements.

PlugCo wholesale plugs all over the world thanks to its dedicated and reliable shipping department. Thus, our customers receive their products at their doorsteps. We have many resellers covering our global market; additionally, we have appointed exclusive distributors for our products in the US, Romania, Australia, Saudi Arabia, United Arab Emirates, Qatar, and Morocco to better serve our expanding customer base.

PlugCo wholesale plugs for their clients without defining a minimum order quantity. We always support our clients and assist them in getting the products and correct quantity they need. This makes us the leading pipe plugs supplier for many traders and end-users.

We will be glad to add you to our family. Give us a call or contact us through our website.

-

- How can we help?

- Here you can chat live to one of our customer support advisors via our Chat system, WhatsApp or Facebook Messenger. You can also send us an email and we’ll reply you back as soon as we can.

- +90 (530) 889 8019

- plugconet

- sales@plugco.net