High-pressure pipe plugs are very important in various industrial and construction applications, serving as reliable solutions for sealing and isolating pipelines under intense pressure conditions.

What is High Pressure Pipe Plug?

A High-Pressure Pipe Plug is typically used in high pressure applications, which standard inflatable rubber plugs cannot hold. Designed to withstand extreme pressure levels, these plugs are a must for protecting infrastructure and personnel from potential hazards.

Types of High-Pressure Pipe Plugs

High-pressure pipe plugs come in a variety of types, each designed to meet specific needs of sealing the pipeline in demanding environments. Understanding these different types is important for selecting the right plug for your application.

Metal-Body High Pressure Pipe Plugs

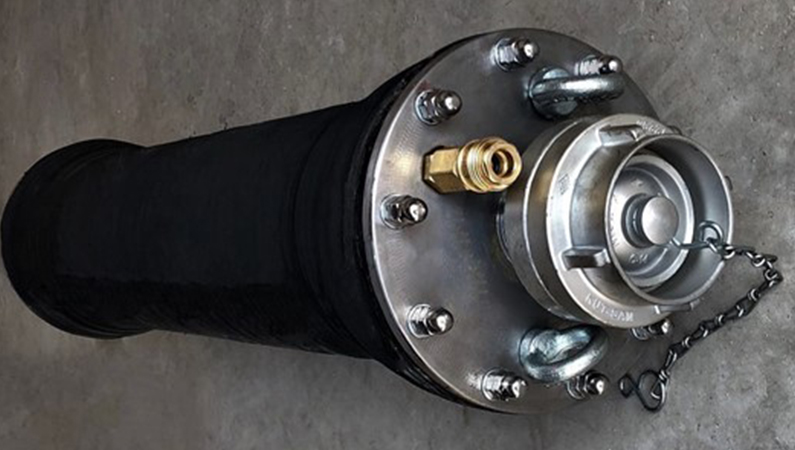

This model of High-Pressure Pipe Plug is made of steel body bonded to extra reinforced SBR+NR Rubber. This Model is single size pipe plug which means that you can use one Model for only one pipe size. For example, you can use HPP1200 for only 1200mm diameter pipe.

This Model is usually used where the pipe is easily accessible (open pipes with no limited access points). Also, this High-Pressure Pipe Plug Model is Ideal for large-diameter pipes.

Inflatable High Pressure Pipe Plugs

Inflatable High Pressure Pipe Plugs use a reinforced bladder or balloon, filled with air, water, or other media to achieve a secure fit. Once inflated inside the pipe, they conform to the pipe’s shape, providing a flexible and effective seal. These plugs are particularly useful in irregular or corroded pipes where a metal-body high pressure pipe plug might fail to seal properly. Preferred when installation must be done through a manhole or when space limitations make metal-body models impractical.

Typically available as multi-size models, meaning a single plug can be used across a small range of diameters, although the range is narrower compared to standard inflatable plugs.

How to Choose the Correct High-Pressure Model?

Selecting the right type of high-pressure plug depends on:

- Pipe diameter

- Pressure requirements

- Access conditions

- Pipe condition (smooth, corroded, irregular, etc.)

By choosing the appropriate model, you can safely conduct the maintenance process by saving both cost and time.

Common Challenges in High Pressure Applications

When working with high-pressure pipe plugs, users often face a variety of challenges that can lead to unwanted situations if not properly addressed. One common challenge is the risk of plug displacement during installation or operation, which can cause sudden pressure release or damage to the piping system. To avoid this, verify that the plug is installed correctly, following PlugCo User Manual. In addition, providing a suitable support to the plug against the back pressure is primordial in high pressure applications.

Environmental factors such as temperature fluctuations can affect the pressure inside the plug for quietly long-term applications. For this, we recommend the end-user to use the Smart Pressure Control System which maintains the inflation pressure in the pre-set value.