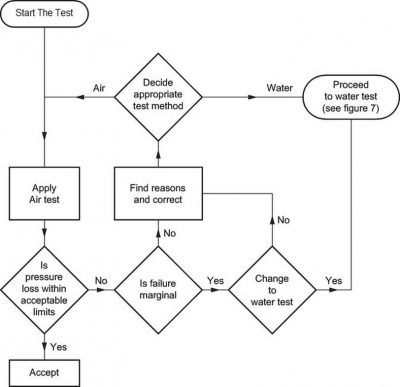

If you have ever been responsible for installing gravity sewer or drain pipes, you already know one thing: they absolutely must be airtight. One tiny leak can mean big problems down the road. That is where air testing comes in, and specifically, testing that follows the EN 1610 standard.

Air testing is quick, cost-effective, and cleaner than water testing. But like any pressurized system, it has its risks. That is why EN 1610 exists, to make sure the process is safe, consistent, and reliable.

What Is EN 1610, and Why Does It Matter?

EN 1610 is the European standard that sets out how to build and test gravity drains and sewers. It’s the rulebook used throughout Europe to make sure new underground pipelines are watertight and properly constructed.

This standard gives you two options for leak testing:

- Water testing: common for deep installations or large systems.

- Air testing: preferred for smaller jobs or where water use is restricted.

If you are doing air testing, especially on flexible or plastic pipes, EN 1610 gives detailed instructions on the correct pressure, duration, and safety precautions. Skip the details, and you risk both a failed inspection and serious on-site hazards.

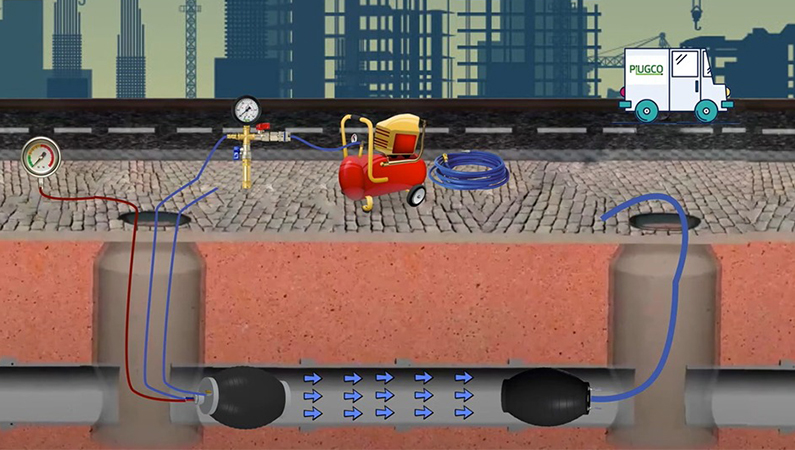

What Equipment Do You Need?

Here is a quick checklist of what you will want on hand before starting an air test:

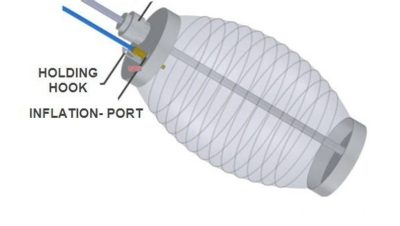

1. Inflatable Pipe Test Plugs

-

- Choose the right size for your pipe’s inner diameter.

- Make sure they are rated for the test pressure and in good condition.

- Always brace them as you don’t want a plug sliding in the line under pressure.

2. Air Supply System

-

- Use a low-pressure air compressor with a good pressure regulator.

- The goal is slow, steady inflation, not a sudden spike.

3. Pressure Monitoring Equipment

-

- A Calibrated Air Control Device provided by PlugCo is essential.

- Some operators prefer digital manometers for real-time tracking, which can be supplied by PlugCo too.

4. Safety and Support Tools

-

- Long air hoses, so you are not standing near the test zone.

-

- Centralizers, to position plugs correctly into the pipe.

-

- Ropes or chains, for safe plug removal.

Types of Air Tests Under EN 1610

EN 1610 allows two specific methods depending on your pipe type:

Method L – Low Pressure Air Test

- Pressure: 110 mbar (0.11 bar)

- Use for: Plastic or flexible pipe systems

- Duration: Shorter test time; simpler procedure

Method H – High Pressure Air Test

- Pressure: 200 mbar (0.2 bar)

- Use for: Rigid materials like concrete or clay

- Duration: Longer and stricter, but necessary for solid systems

Each method has its own timing chart based on pipe diameter and length, you will want to reference EN 1610 for exact test durations.

Air Test as per EN1610

Air testing a gravity pipeline according to EN 1610 is not complicated, but it does require attention to detail. Follow the proper steps, use quality equipment, and always prioritize safety. Whether you are pressure testing a short residential run or a long industrial line, these standards are designed to help you get the job done right the first time.

If you are unsure about pressure values, allowable drops, or test durations, always consult the official EN 1610 standard or consult PlugCo’s team.