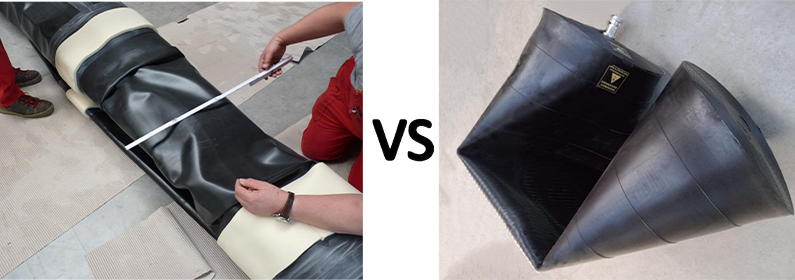

The correct selection of pipe plugs stands as a critical factor in pipeline maintenance because it ensures both safety and operational efficiency and produces an effective seal. Among the numerous pipeline obstruction devices available conical and cylindrical pipe plugs represent two of the most common models. Both pipeline blocking plugs serve identical functions but their design shapes and sealing principles differ along with their specific use applications.

Design and Functionality

The cylindrical pipe plug expands outward through its straight parallel sides as it inflates. The seal forms when the plug expands radially because it matches the internal diameter of the pipe perfectly. The design of cylindrical plugs works best when used in pipes that have regular uniform diameters and smooth inner surfaces. The cylindrical plug design achieves its best sealing pressure performance for high-pressure applications such as hydrostatic or pneumatic pipeline pressure testing.

The conical shape of pipe plugs extends outward forming a truncated cone structure. Their tapered design enables conical plugs to handle pipes with various sizes particularly well for working with pipes that show signs of interior damage. Conical plugs work effectively to seal pipes even when the diameters vary slightly or when deposits or corrosion are present (Sharpen objects are not tolerated).

Pressure Handling and Performance

The uniform distribution of pressure across cylindrical plugs allows them to withstand stronger back pressure than conical plugs do. Standard cylindrical plugs designed for water or sewer testing reach back pressure capacities exceeding 2.5 bar (36 psi) based on their dimensions and material characteristics.

The performance range of conical plugs extends from low to moderate back pressures up to 1.0 bar because they offer flexibility in terms of diameter compatibility. The selection of conical plugs happens primarily when work demands involve different pipe dimensions together with difficult installation requirements.

Although cylindrical plugs handle more back pressure than Conical plugs, they happen to require bracing and special supporting to withstand high back pressures.

Installation Considerations

The tapered design of conical plugs makes their insertion process simpler. The tapered structure enables pipes to become more accessible during installation especially when working with sediments or small diameter fluctuations. The installation of conical plugs demands proper care because excessive inflation together with incorrect anchoring methods can cause the plug to shift out of position.

Once properly aligned during insertion cylindrical plugs become stable and maintain a tight seal that shows minimal movement. The plug’s stability becomes essential when performing extended tests under elevated pressure conditions.

Choosing the Right Plug: Practical Examples

The use of cylindrical plugs is best suited for uniform new pipelines. The plug excels at hydrostatic testing of new pipelines and pipe sections because it provides both tight sealing capabilities and high-pressure resistance when the exact pipe dimensions are available.

Conical plugs serve best for work with older pipelines that have varying diameters because they provide flexible installation capabilities especially for pipes with irregular surfaces and diameter changes caused by aging and deposits.

Conical vs. Cylindrical Pipe Plugs

| Feature | Cylindrical Pipe Plug | Conical Pipe Plug |

| Shape | Straight sides | Tapered (truncated cone) |

| Best Fit | Uniform, smooth-diameter pipes | Pipes with slight diameter variations or damage |

| Pressure Capacity | High (up to or above 2.5 bar) | Low to moderate (up to 1.0 bar) |

| Installation | Requires precise alignment and support | Easier insertion, flexible fit |

| Ideal Application | New pipelines, hydrostatic/pneumatic testing | Old pipelines, irregular inner surfaces |

| Seal Stability | Excellent when installed correctly using special support | Requires careful anchoring |

Back Pressure and Plug Stability

Back pressure is the force exerted on a pipe plug by the fluid behind it, typically measured in bars, where 1 bar corresponds to the pressure from a 10-meter water column. Controlling back pressure is essential to prevent the plug from sliding or bursting during pipeline operations. Proper inflation ensures that the frictional force between the plug and the pipe surface is sufficient to resist this pressure. The fundamental safety condition is:

Ffriction≥Fback pressure

To accurately calculate back pressure and select the right plug, refer to PlugCo’s detailed Back Pressure Calculation guide. Additionally, PlugCo offers a Smart Plug system that dynamically monitors and controls back pressure to enhance operational safety and prevent plug displacement. You can learn more about this advanced solution in the previously written article: How to Prevent Inflatable Plug Sliding in Real Pipeline Condition

Material and Size Range

PlugCo manufactures their products in a broad diameter spectrum that includes small sizes (beginning at 35 mm) all the way to extensive diameters. The plugs use reinforced rubber composites which make them resistant to chemicals and abrasion and capable of working in diverse temperature ranges.

The selection between cylindrical and conical pipe plugs depends on how the pipeline conditions match up with the required testing pressures and the desired ease of installation. The cylindrical design works best for high-pressure testing of uniform pipes yet conical plugs perform better in cases that require flexible fits and quick insertion capabilities.

Knowledge about these differences leads to safer projects while minimizing testing mistakes along with faster maintenance operations. For detailed product information and specific recommendations users should consult the technical team at PlugCo or review the products catalog.