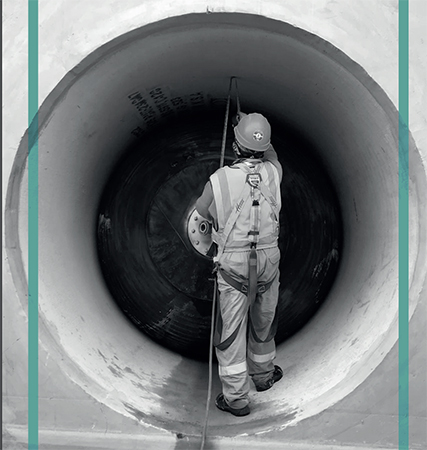

Choosing the right pipe plug isn’t just about picking a plug that fits. It’s about safety, performance, and making sure your maintenance or testing job goes off without problems. At PlugCo, we’ve helped customers in over 65 countries figure this out, and we’re happy to break it down for you.

So let’s talk about the 4 most important things to consider when selecting a pipe plug (and how to avoid costly mistakes).

Know Your Pipe Size (Not Just “About or Around 600 mm”)

This may seem obvious, but you would be surprised how often people guess or try to estimate it. Pipe plugs are designed to expand and seal properly based on the inner diameter (ID) of the pipe. Even being inaccurate by a few millimetres can result in poor sealing or, worse still, the plug sliding out

Tip: Get the accurate pipe specifications before you order. PlugCo offers both multi-size plugs (for flexibility) and single-size plugs (for exact fits), depending on what you need.

Don’t Forget About Back Pressure!

Imagine your plug is in place. Now consider what is inside the pipe. Is it water, air or oil pushing back on the plug with force? That is back pressure, and if your plug isn’t designed to withstand it, things can quickly go bad.

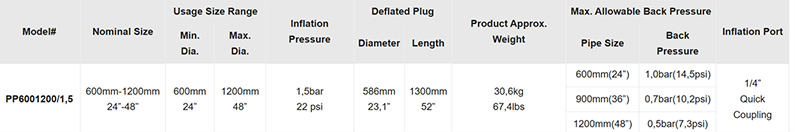

PlugCo clearly labels the maximum back pressure each plug can handle. For example, the PP6001200/1.5 model can manage 0.5 bar at the larger diameter and 1.0 bar at the smaller end.

Important Note: If you’re performing a leak test using two plugs (filling the section between them with water or air), the test pressure applied inside the pipe will act outward against both plugs. This test pressure is the same as back pressure. So always ensure that the test pressure does not exceed the plug’s rated back pressure.

Tip: Always check the exact back pressure of your system and match it with the plug’s rating, not the other way around. If you are not sure, we also have a Smart system that can tell the exact back pressure of your system, to know more about it you can check this blog: How to Prevent Inflatable Plug Sliding in Real Pipeline Condition | PlugCo | plugco.net

What is inside Your Pipeline? (Media Compatibility Matters)

Water, air, oil, chemicals… they all behave differently. And they don’t treat rubber the same way.

That’s why PlugCo uses different materials depending on the application:

- SBR+NR rubber for water and wastewater.

- Nitrile rubber (NBR) for oil, gas, and petrochemical pipelines.

Tip: If you’re working in oil & gas, don’t even think about using standard rubber plugs. Get the chemical-resistant like PlugCo’s Oil & Gas Series plugs.

The Flow During Maintenance? Use a Bypass Plug

Sometimes, you can’t shut down the whole line just to run a test or do a repair. That’s when a plug with a bypass connection becomes your option.

PlugCo’s PTP models and GPB models let the flow continue through the pipe while still sealing off the area you’re working on. It’s ideal for stormwater lines, sewer bypasses, or industrial systems that need to keep running.

Tip: If keeping flow uninterrupted is a must, look for models with bypass options. PlugCo has several sizes available.

PlugCo Helps You Get It Right

A pipe plug might seem like a small part of a massive system, but picking the wrong one can lead to big problems: leaks, lost time, safety risks, and blown budgets.

At PlugCo, we’re not just selling rubber. We’re helping engineers, contractors, and field crews do the job safely and effectively.

If you still not sure which plug is right for your setup? Get in touch with PlugCo, and we’ll help you figure it out. sales@plugco.net