When it comes to testing and blocking pipes, pipe plugs are super useful tools. But have you ever heard of a bypass connection? If you’re new to this field or just curious, don’t worry, we’ll explain it in a simple way!

- What is a bypass connection?

- Why it’s important?

- Which PlugCo products have bypass options?

- A comparison table of plugs with and without bypass

What Is a Bypass Connection?

A bypass connection is a special feature on a pipe plug. It allows liquid or air to flow through the plug, even while the plug is inside the pipe.

Think of it like this: You want to block a pipe, but still need water or air to go from one side to the other. That’s when a bypass plug becomes a need!

Without a bypass, a plug simply stops all the flow. With a bypass, it blocks and allows the flow to keep going at the same time.

Why Use a Pipe Plug with a Bypass?

There are several situations where using a pipe plug with a bypass connection is not just helpful, it’s necessary. Let’s look at the most common reasons in more detail:

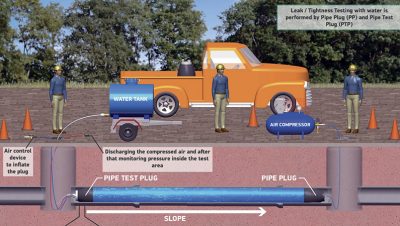

1. Water Leak Testing Without a Manhole

When you’re testing a new pipeline for leaks, you usually fill the pipe with water and apply pressure. But here’s the problem:

If there’s no manhole (or any opening in the Middle of the testing area), how do you get water inside the pipe?

That’s where the bypass connection comes in!

- You insert a pipe plug with a bypass into one end of the pipe and another normal pipe plug into the other end.

- Then, you pump water through the bypass to fill the pipe.

- Once filled, the same bypass can be used to apply pressure for the test.

Without a bypass, there’s no easy way to fill the pipe or run the test, especially in long pipelines or systems without manholes. So in these cases, the bypass is a must. If you need to know more about the water leak test process you can refer to this Video: https://www.youtube.com/watch?v=ndcooFgCZ10&t

2. Drainage and Maintenance – Letting Water Out Safely

This is about removing leftover water or liquids from the pipe after work or testing is done.

- Example: After doing a leak test, some water remains inside the pipe.

- You can use the bypass to slowly drain that water through a hose.

- This is especially useful when there’s no slope or gravity drain available.

Think of it as an answer of: “How do I empty the pipe safely?”

3. Air Release or Pressure Control – Managing Test Pressure

This is about controlling air or water pressure during the test, not after.

- Example: While you’re filling the pipe with water for testing, air pockets can get trapped.

- Those air pockets can cause false results or dangerous pressure spikes.

- The bypass lets you release air or connect a pressure gauge to monitor and adjust pressure.

Think of it as an answer of: “How do I make the test safe and accurate?”

PlugCo Products With and without Bypass

PlugCo has two main plug types for pipeline testing and blocking:

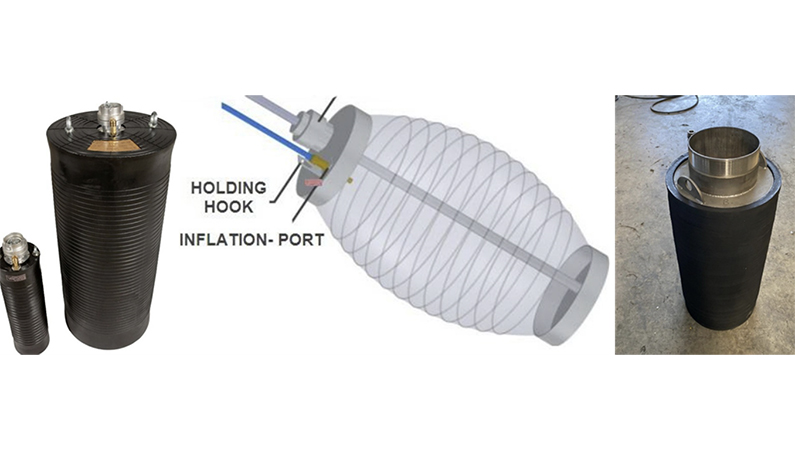

PP Model – Pipe Plug (Without Bypass)

This is a basic plug used to fully block a pipe. It does not include a bypass connection. It’s ideal when you need to stop the flow completely, like for maintenance or sealing off unused lines.

Example: PP5001000 → For pipes 500–1000 mm, no bypass connection.

PTP Model – Pipe Test Plug (With Bypass)

This plug is designed for leak testing and filling the pipeline through the plug itself. It has a built-in bypass connection, allowing you to fill, test, or drain the pipe without a need of manholes. Especially useful in long pipe sections where no access point exists.

Example: PTP5001000 → Same pipe size as the PP version, but with a bypass.

What If the Pipe Contains Chemicals, Gas, or Hydrocarbons?

Pipelines don’t always carry just water or air. In many industries, like oil & gas, chemical plants, or fuel Systems, pipes can be full of chemical fluids, gas, or hydrocarbons. These substances require special materials and more durable plug construction, like a nitril rubber that can resist all that.

To solve this, PlugCo has developed specialized models based on the same concept as the PP and PTP plugs. These are called GP and GTP models. Just like before, the GP is the version without a bypass, and the GTP includes a bypass connection.

What makes them special is the material: they are made from nitrile rubber, which is resistant to chemicals, oil, gas, and hydrocarbons. That makes them ideal for use in industrial pipelines where standard rubber would not last. You can learn more about these models by checking this blog: (publish the link of this article when it is accepted Why Nitrile Rubber Is Essential for Oil & Gas Applications)

Simple Rule to Remember:

- If the model is PP or GP → It’s a Pipe Plug, no bypass.

- If the model is PTP or GTP → It’s a Pipe Test Plug, and has a bypass.

This also makes PlugCo’s system very user-friendly, becasue you can choose the same size range, and just pick whether you need a bypass or not.

| Model | Plug Type | For Fluids Like… | Bypass |

| PP | Pipe Plug | Water, wastewater, air | No |

| PTP | Pipe Test Plug | Water, wastewater, air | Yes |

| GP | Gas Plug | Gas, oil, chemicals | No |

| GTP | Gas Test Plug | Gas, oil, chemicals | Yes |