When testing pipelines, especially using pipe plugs, one word that keeps coming up is “back pressure.” But what does it really mean, and why should you carefuly consider it? No worries, we’ll break it down in simply in this article and explain how PlugCo helps you manage it safely and effectively.

What is Back Pressure?

Imagine you block one end of a pipe and start filling it with water. The water pushes against the blockage. That pushing force is what we call back pressure.

In pipeline testing, back pressure is the force pushing back on the pipe plug, the device that blocks the pipe during tests. If the pressure becomes too high and the plug isn’t strong enough, the plug can slip or even shoot out, and that’s dangerous.

Why is Back Pressure Important?

Here’s why you need to understand back pressure:

- Safety: Too much back pressure can cause a plug to fail or fly out. This puts workers and equipment at risk.

- Accurate Testing: If the plug doesn’t hold, your test results won’t be reliable.

- Proper Equipment Use: Every plug has a limit. If you don’t calculate back pressure correctly, you could damage the plug or the pipe.

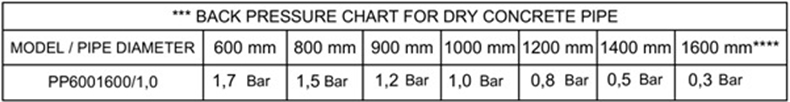

In the photo above, you can see the damage caused to a pipe plug when the pressure limit was exceeded: The client used a the PP6001600/1.0 model and according to datasheet, this plug can handle 0.8bar back pressure at 1200mm:

However, the client used this plug in a 1200 mm pipe where the actual back pressure was 1.5 bar almost double the rated capacity.

This excessive pressure caused the plug to deform and fail, leading to potential safety hazards and equipment damage.

How to Calculate Back Pressure (The Easy Way)

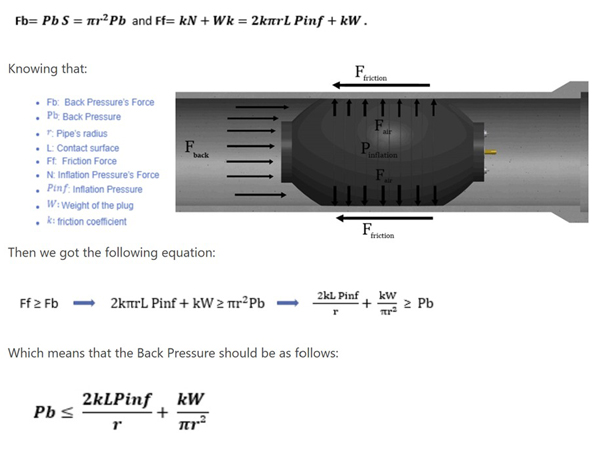

PlugCo provides a clear formula to calculate back pressure. Here it is:

However, there is an easy way as well to consider for back pressure while giving an order.

Back Pressure (Bar) = Height of Water Column (meters) ÷ 10

Let’s say you want to block a pipe of 600mm inner diameter and the Height of water inside that pipe is up to 5 meters:

5 meters ÷ 10 = 0.5 bar of back pressure

So the plug to be used should resist 0.5bar at 600mm pipe.

But remember, real life isn’t always perfect. The pipe may not be smooth or dry. That’s why PlugCo always recommends using a safety margin and choosing plugs rated above your expected pressure.

Back Pressure of Pipe Plug | PlugCo | plugco.net

How PlugCo Helps You Manage Back Pressure

At PlugCo, we don’t just sell pipe plugs, we give you the tools and knowledge to use them safely.

Here’s how:

- Strong, tested products: Our pipe plugs are built to handle high back pressure, some up to 6 bar (that’s a lot!).

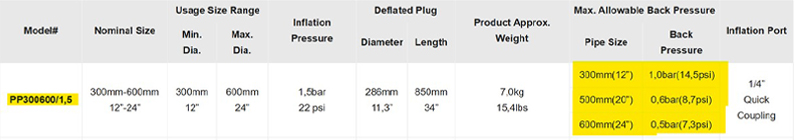

- Clear specifications: Every PlugCo product comes with details about how much back pressure it can hold and at which exact diameter.

- Back pressure calculator: On our website, you can find guides and examples to help you calculate the right plug and inflation pressure. (I need the link for calculation I couldn’t find it)

- Custom solutions: Need a plug for special conditions? We can help with that too, just Contact sale@plugco.com and we can select the right plug for your application together.

Want to Go Even Smarter? Use PlugCo’s Smart Plug

PlugCo’s Smart Plug is an advanced testing tool with:

- Real-time back pressure monitoring

- Pressure alarms for safety

- Accurate readings even in dirty, wet, or non-standard pipes

This takes the guesswork out and makes your pipeline testing much safer and more precise. How to Prevent Inflatable Plug Sliding in Real Pipeline Condition | PlugCo | plugco.net