When performing pressure tests on pipelines, whether using air or water, proper connection and control equipment is essential for safety and test accuracy. Two small but critical accessories in PlugCo’s testing system are the Air Test Adaptor and the Air Discharge Adaptor.

These adaptors ensure that air is introduced and monitored safely and efficiently, while also allowing trapped air to be discharged for accurate test results.

What Is PlugCo’s Air Test Adaptor?

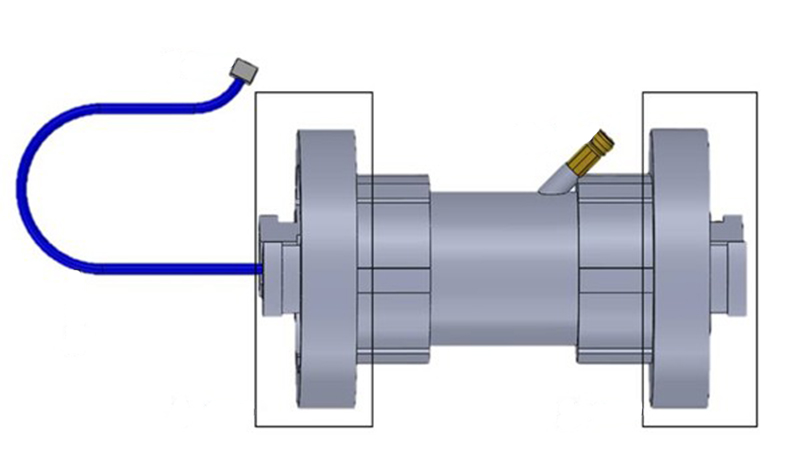

The Air Test Adaptor is a specially designed connection fitting that allows controlled and secure injection of air into a pipe section during Air Leak-tightness tests (EN 1610 / ASTM F1417)

It is typically connected to the inflatable plug’s bypass port, and used to monitor both inlfation pressure and air test pressure.

What Is PlugCo’s Air Discharge Adaptor?

The Air Discharge Adaptor serves a crucial safety function: it allows for controlled and safe release of air from the test section during Water Leak-tightness tests.

Why Are These Adaptors Important?

1. Safe Connection and Disconnection

- Both adaptors allow secure hose connections without risk of air leakage or accidental blowouts.

- Quick-connect or threaded fittings and full compatiblity with different models of PlugCo’s pipe test plugs.

2. Controlled Air Management

- The Air Test Adaptor enables you to fill the pipeline with air at a controlled rate, preventing overpressurization or damage to the pipe and plugs.

- The Air Discharge Adaptor ensures a the releasing of air in the test area and monitoring of pressure test.

3. Pressure Test Accuracy

During low-pressure air testing (e.g., 110–200 mbar as per EN 1610), even small air leaks can skew results. PlugCo’s adaptors:

- Minimize uncontrolled air losses

- Provide sealed, leak-free air injection and discharge

- Enable stable pressure holding throughout the test duration

How Are the Adaptors Used?

Air Test Adaptor – Installation Steps:

- Connect the adaptor to the bypass port of the upstream plug

- Attach the air hose from the compressor or test control system.

- Monitor air flow and pressure using a smart control system or pressure gauge.

Air Discharge Adaptor – Installation Steps

Here is how we typically install the air discharge adaptor on site:

- Connect the adaptor to the bypass port of the pipe test plug.

- Attach a vent hose or discharge line to direct air safely away from the operators and equipment.

- Watch the flow: once water starts flowing steadily, hook up the pressure gauge. That is your signal to begin controlling the test pressure accurately.

Safety Tips from the Field

- Always use long hoses to keep your team well clear of any potential blowout zone.

- Double-check all adaptor fittings for tightness before starting the pressure test. Don’t skip this.

A Few Final Words

PlugCo’s Air Test and Air Discharge Adaptors might not look like much, but they are key players in running a safe and accurate pressure test. From our experience, they help ensure:

- Smooth and controlled airflow

- Reliable, leak-free connections

- Safe venting without sudden releases

- Compliance with EN and ASTM test standards

If you are serious about both precision and safety, these adaptors are a must-have in your pipeline testing toolkit.