In our previous article we have outlined the Leak Test for sewer, storm, drain pipelines by “Water Filling through Manhole” method. In this article we would like to explain the “Water Filling through Plug” method and explain its two different applications. Both applications are in accordance with the EN 1610 Standard for construction and testing of drains and sewers.

LEAK TEST BY “WATER FILLING THROUGH PLUG” METHOD

This method consists of two control practices, depending on whether you use a manual pressure test pump or not.

Necessary equipment as below:

- 1 Pcs Pipe Plug and 1 Pcs Pipe Test Plug

- Air Control Device

- 10-meter Air Hose

- Air Discharge Adaptor

- Water Hose

- Air Supply

- Manual Pressure Test Pump

WITH MANUAL PRESSURE TEST PUMP

Connect the air hose to the Pipe Plug. And then, connect air hoses and the water hose to the Pipe Test Plug with Air Discharge Adaptor which enables quick coupling for easy treatment.

Place both Pipe Plug and Pipe Test Plug into the pipeline by taking the slope of the pipeline into consideration (shown at the below video). Duly inflate both Pipe Plug and Pipe Test Plug synchronically. Then charge the test area with water through Pipe Test Plug until receiving water from the end of the air hose of the discharge adaptor (for discharging the compressed air or pressurizing the pipeline). Close water supply and connect Manual Pressure Test Pump to the air hose.

Adjust the pressure to 0,5 bar as in the formula X+H/10=0,5 (where X is the pressure created by the Manual Pressure Test Pump and H is the static pressure). Remove the Manual Pressure Test Pump and connect the Pressure Gauge to monitor the pressure is kept at 0,5 bar for at least 30 minutes to fulfil the requirement of EN 1610.

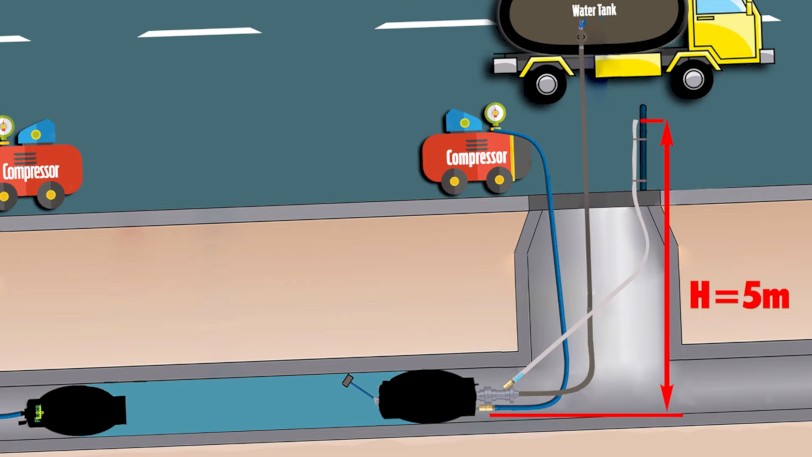

WITHOUT MANUAL PRESSURE TEST PUMP

Apply above stated steps until receiving water from the end of the air hose. Stabilize the air hose (for discharging the compressed air or pressurizing the pipeline) to keep it vertical. Adjust the water level to 5 meters. Note that; 5-meter water head is equivalent to 0,5 bar (50 kPa)

Close water supply and mark the water level. Monitor for at least 30 minutes to fulfil EN 1610 requirement as below:

The variation of water volume during the test shall be measured with and accuracy of 0,1l and recorded with the head of water at the required test pressure.

The test requirement is satisfied if the variation of volume of water during the test is not greater than:

- 0,15 l/m2 during 30 min for pipelines;

- 0,20 l/m2 during 30 min for pipelines including manholes;

- 0,40 l/m2 during 30 min for manholes and inspection chambers;

Note m2 refers to the wetted internal surface.

As a final step for both practices, deflate the Pipe Plug and Pipe Test Plug, remove all connections and apply necessary after-use-maintenance steps.

As an experienced pipeline leak test implementer, PlugCo offers further assistance at the email address sales@plugco.net and at mobile +90 533 545 81 97.