Here is a practical walk-through of how to conduct a proper air test, whether you are using Method L or Method H outlined in EN1610 Standard. For more details about what these methods refers to check the previously written article: How to Test a Gravity Pipeline with Air According to EN 1610

Step 1: Preparation of the Pipe Section

- Clean the inside thoroughly as dirt and debris can cause plug and/or test failures.

- Visually inspect plugs, hoses, and all the accessories before use.

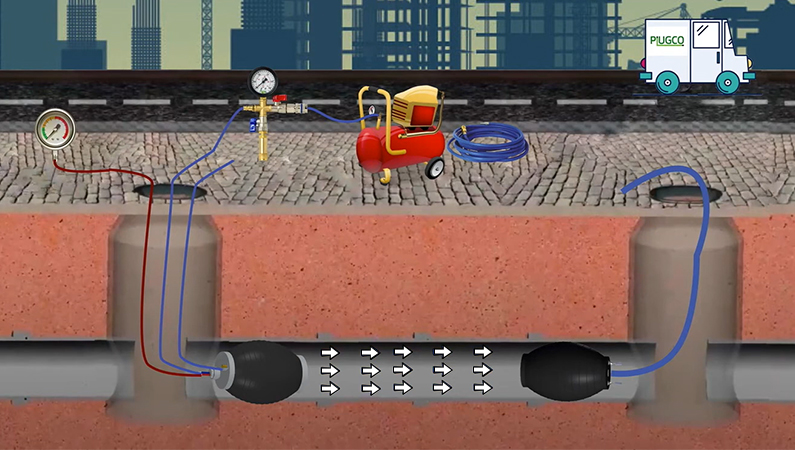

- Block off both ends of the section with test plugs.

- Check your safety zone and ensure that no one is standing near plugged ends!

Step 2: Install and Inflate the Plugs

- If needed, use a centralizer to position the plugs accurately into the pipe.

- Inflate slowly using PlugCo’s Calibrated air control device attached to a regulated air compressor.

- Secure the plugs tightly to Avoid their sliding due to the back pressure force.

Step 3: Fill Air Pressure

- Gradually fill the section with air to the required test pressure (110 or 200 mbar).

- Let the system stabilize for at least 5 minutes before timing.

- Expect a slight pressure drop as the air temperature evens out.

Step 4: Begin the Test

- Once stabilized, begin timing according to EN 1610.

- For Method L: Monitor pressure over the test period. A slow drop is okay as it just has to stay within the allowed limit.

- For Method H: Watch carefully. This is a stricter test with tighter tolerances.

Step 5: Check the Results

- If the pressure drop stays within the standard’s limits, you are good to go, and the pipe passes the test.

- If it drops too quickly, you have got a leak. Use soapy water or recheck connections before trying again or before changing the testing method to water when possible.

Safety First and Always

Air testing can be dangerous if done carelessly. High-pressure plugs have been known to launch when improperly secured, and sudden air bursts can cause injury. A few golden rules:

- Never stand in the line of a pressurized plug.

- Use long hoses to monitor pressure from a distance.

- Never exceed the pressure rating of your test plugs.

- Follow PlugCo’s safety manual alongside EN 1610.

After the Test

- Release the air slowly and safely, and avoid sudden decompression.

- Fully deflate and remove the plugs with caution.

- Inspect plugs and hoses before storing them for next time.